Windpower king looks to be Oklahoma

Notice the land area in MA is almost same as TX!

(explanation is probably large offshore wind farms

in MA.)

source --- http://www.nrel.gov/docs/fy08osti/42794.pdf

Overview

50% efficiency mystery

Introduction

Theory

Principle

of operation

Wind

power equation

Theoretical

wind turbine efficiency analysis is sketchy

Betz

limit

Betz

limit decoded

Understanding

the Betz results -- my Wikipedia edit

Betz

model applied to modern turbines

Wind turbines

2.5

Mw Clipper (USA)

Nordex

2.5 Mw electrical specs (German)

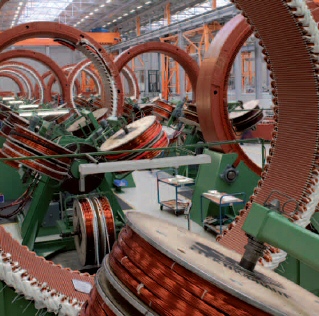

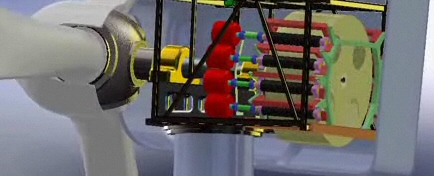

Direct drive wind turbines

2.3

Mw Enercon gearless (German)

Notes

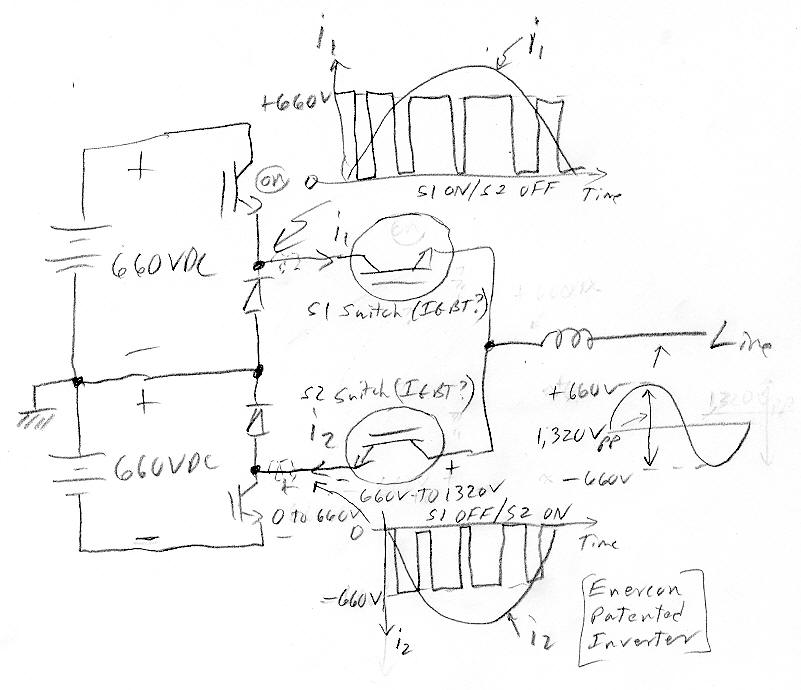

on Enercon patents

E-126

7 Mw world's largest wind turbine

Enercon

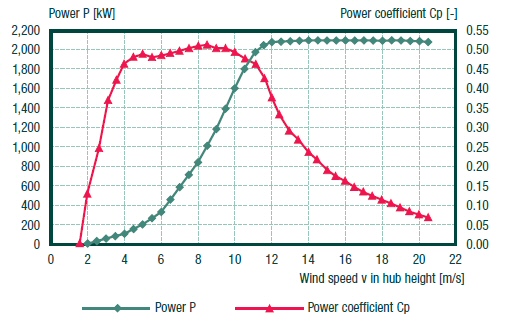

2.0 Mw gearless spec

Siemens

3 Mw direct drive wind turbine (SWT-3.0-101)

Northern

Power 2.3 Mw direct drive turbine

Wind turbines (cont)

2.1

Mw from India (Suzlon)

3

Mw Acciona (Spanish design)

Cape

Wind ---Offshore wind farm on Cape Cod

Deepwater

wind --- wind turbines off the coast of Block Island RI

Alstom 6 MW turbine -- (French/Spanish)

offshore turbine

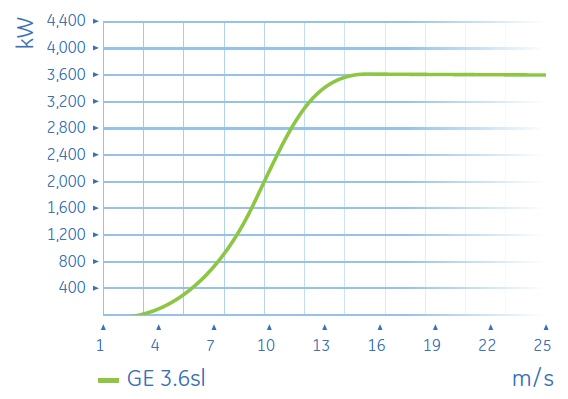

GE

3.6 Mw (offshore) wind turbine (cancelled)

GE

Wind 2.5 Mw turbine (USA, formerly Zond/Kenetech)

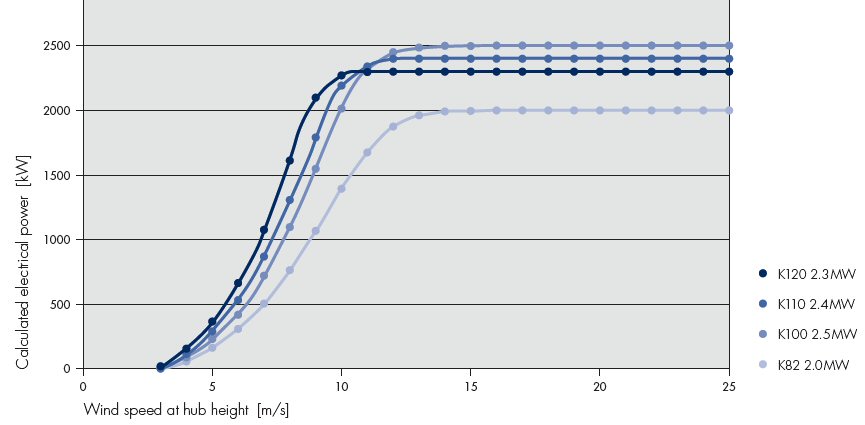

Kenersys

2.5 Mw turbine model K100

Types of generators

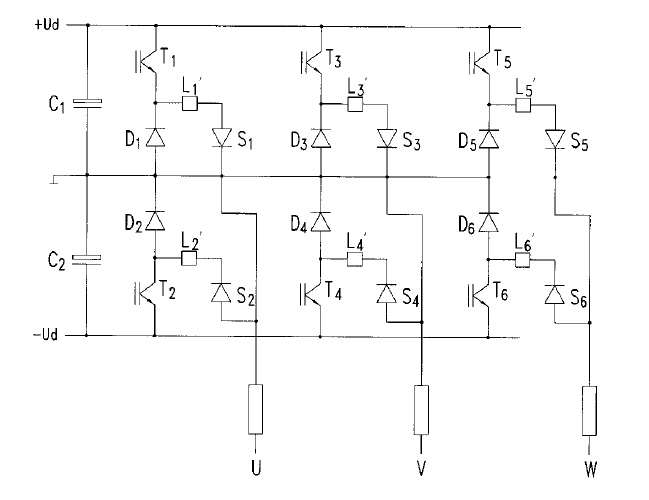

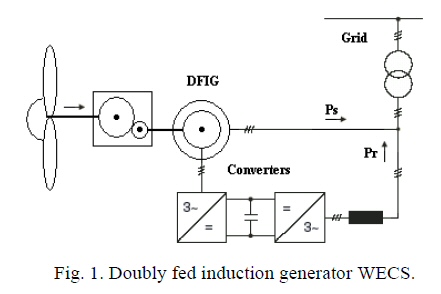

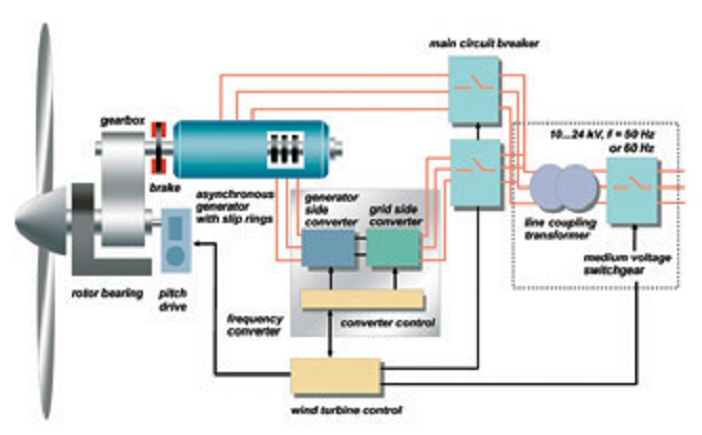

Double-fed

induction generator

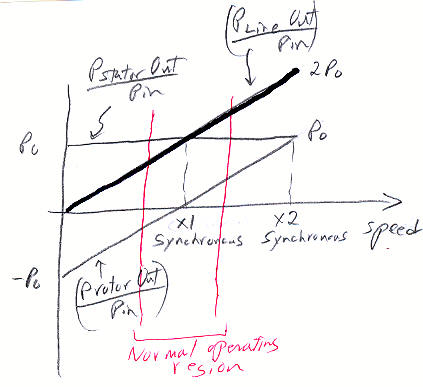

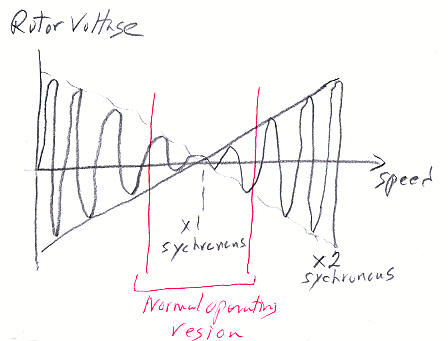

How

a double fed induction generator works in sketches

PM

generators

Electronics

High

capacity IGBT's

Cost

comparison to 1,000 Mw nuclear plant

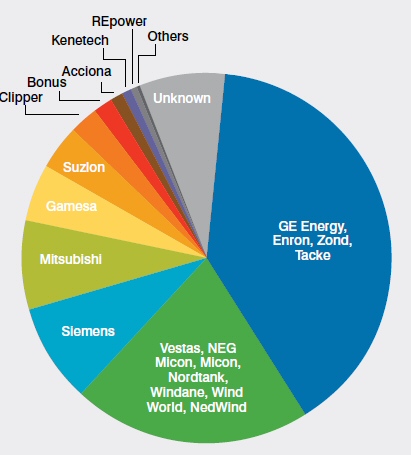

Wind turbine manufacturers

Wind turbine history

1.5

Mw Chinese turbine goes up near Boston

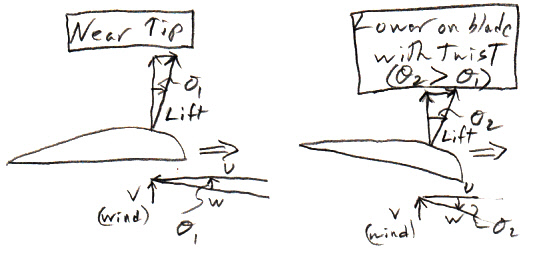

Blade characteristics

Blade

as airfoil

How

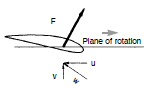

blade 'airfoil' is driven forward

Blade

lift and rotation

How

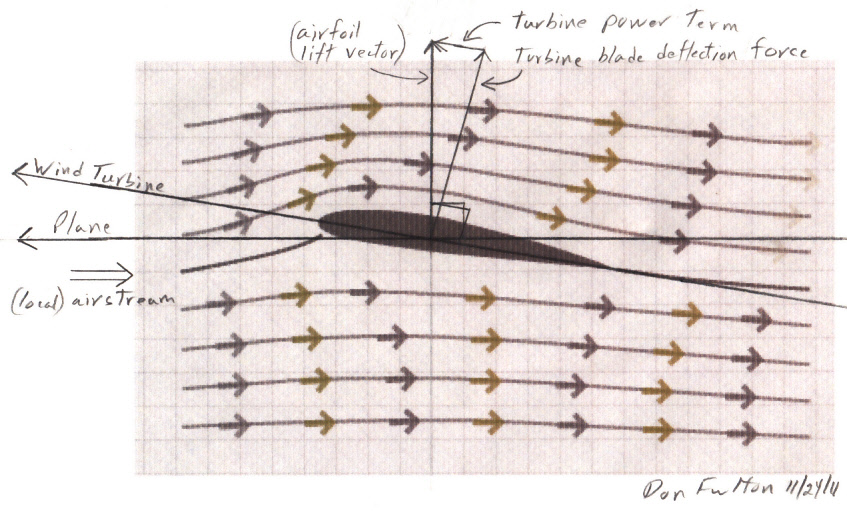

is the lift of a wind turbine blade different from an airplane wing?

Turbine

blade view

Explaining

the shape of the blade

Blade

numbers from 1999 Bonus Turbine paper

Alternate wind turbine designs

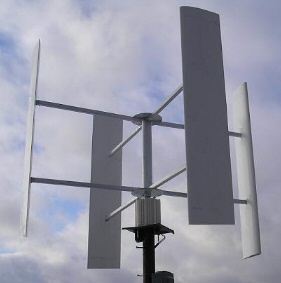

Vertical

wind turbines

Savonius

(vertical, drag) wind turbines

Darrieus

(vertical, lift) wind turbines

Makani

Flying Wing turbine

Appendices

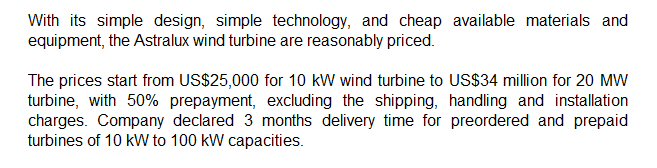

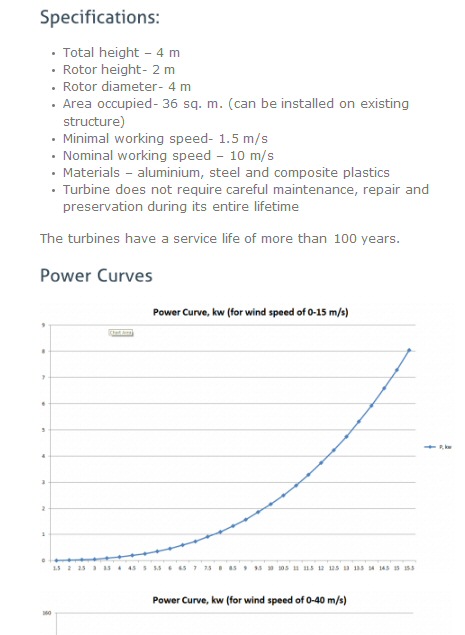

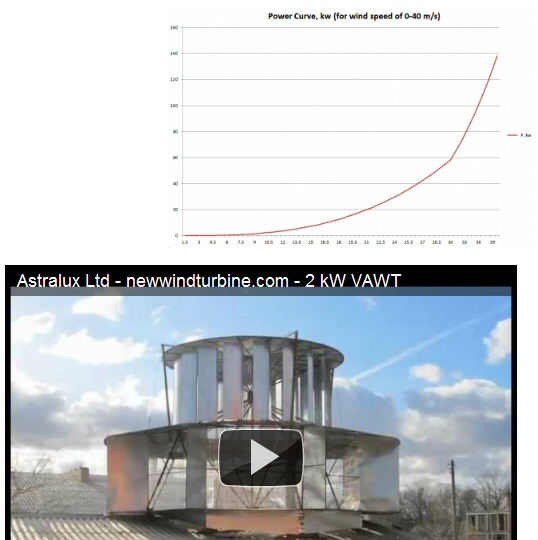

Astralux

Ltd --- a wind turbine scam

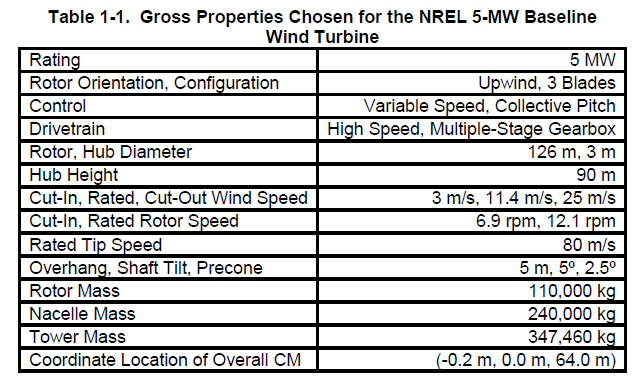

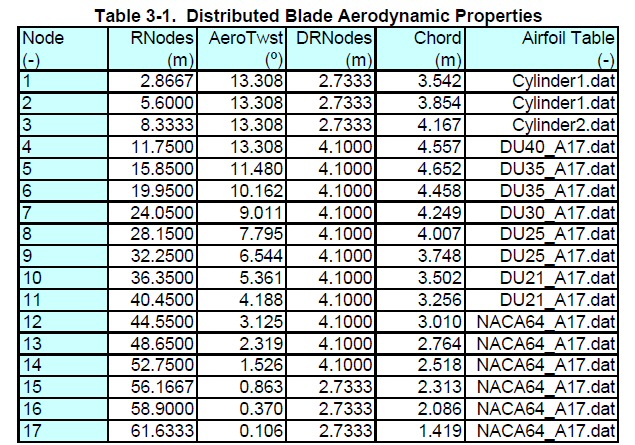

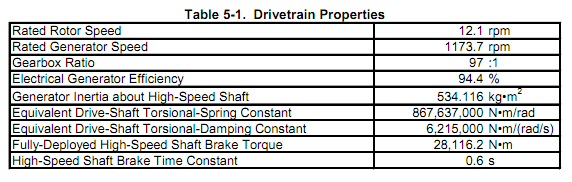

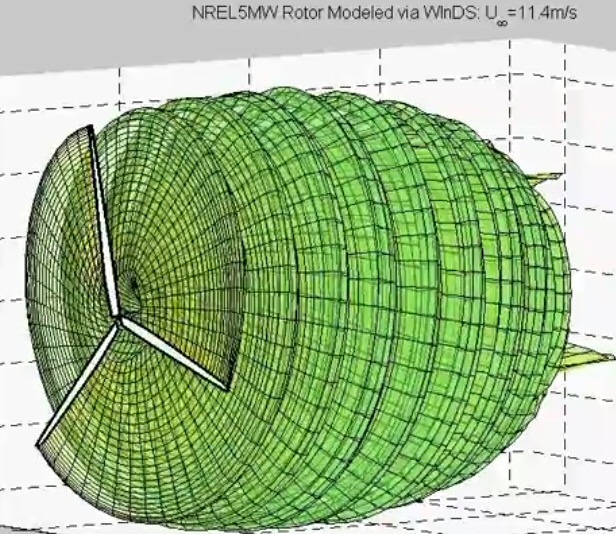

Detailed

spec of 5 Mw offshore wind turbine

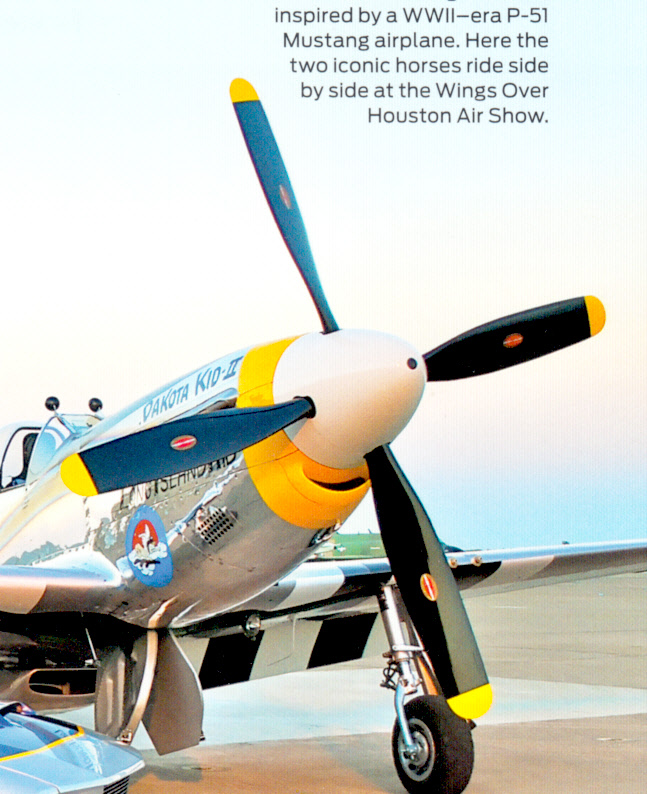

P51

airplane propeller

Misc

wind turbine (old stuff)

References

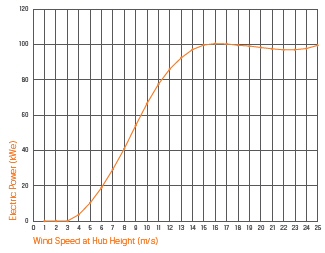

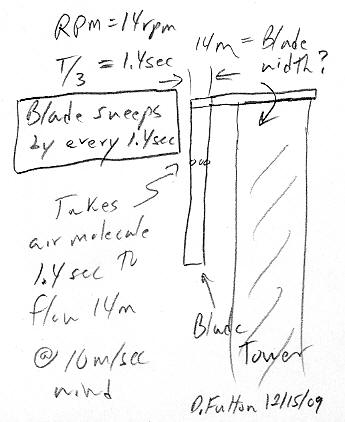

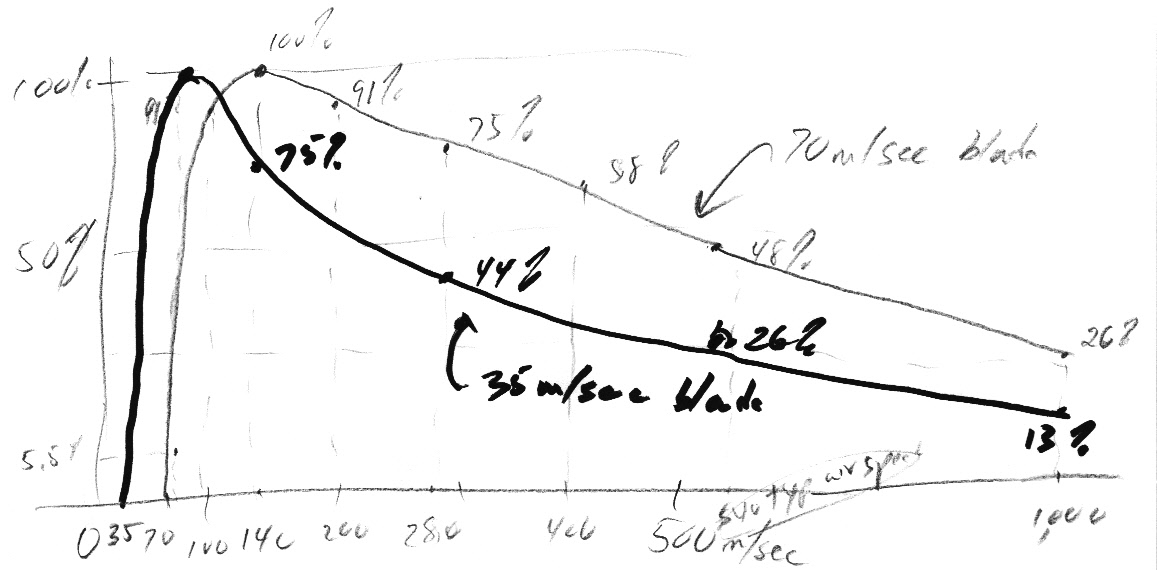

4 m/s = 9 mph

min speed (cut-in)

10 m/s = 22 mph

midband speed (75 - 80% rated power)

12.5 m/s = 28 mph

rated power speed (100% power 12.5 to 25 m/sec)

25 m/s = 56 mph

turbine stop (> 25 m/s)

70 m/s = 156 mph

survivable (storm) wind

Turbine wind bands (above) are nearly independent of the turbine power rating. Power scaling is done by varying the size of the turbine: power going up as the radius squared, and the rotation period decreases as 1/radius. A large 2.5 Mw wind turbine has a radius of about 45m, a period of about 3 seconds, and is almost 50% efficient mid-band.

Competing on cost (update 11/24/14)

A story in

the NYT today indicates that wind (and solar too) is beginning to achieve

a long sought goal, at least in the midwest and south where is lots of

wind. Utilities report these alternative energy sources in these regions

are successfully competing on price with fossil fuels (even gas) without

subsidies.

This is the result of years of hard won engineering, nurtured by subsidies,

to produce a competitive reliable energy product as I have documented in

this essay. The NYT story gives these costs being paid by utilities for

future contracts to buy power (power purchase agreements): natural gas

6.1 cents/kwh (baseline) and coal 6.6 cents/kwh (baseline). Without subsidies

wind is as low as 3.7 cents and solar 7.2 cents; with subsidies wind is

1.4 cents/kwh and solar 5.6 cents/kwh.

Overview

Modern wind

power turbines are physically huge with (peak) outputs in the low Mw range.

Towers are about as tall as 25 story buildings and blade dia is larger

than a football field. Modern large turbines incorporate two engineering

advances over older sub-Mw turbines that have increased wind capture efficiency:

variable blade speed (made possible by IGBT electronics) and variable blade

pitch (older turbines relied on blade stall to limit power capture in high

speed winds).

Each large wind turbine is a mass produced equivalent to 1/1,000th (roughly) of a standard 1,000 Mw power plant They cost about x1.3 more than a conventional coal plant making them (with a 30% subsidy) roughly cost competitive. They are now far more cost competitive than solar. Wind power is on track to grow to provide about 20% of the country's electric power in 20 years (2030), or 200 Gw from about 200,000 turbines. At 5 million dollars/turbine this is an investment of one trillion dollars, equivalent to 10,000 dollars/household (assuming 100 million households in USA).

Will drastically lower natural gas prices kill off wind? (4/12)The current state of the art in wind turbines (onshore) is 2.5 Mw, though the installed base is mostly 660 kw to 1.5 Mw. The 2.5 Mw limit is primarily set by what is movable by truck. For offshore or riparian (where movement is by ship) the state of the art is somewhat larger, 3.6 Mw to 7.5 Mw, basically scaled up 2.5 Mw's. Wind turbines like solar are rated at peak power. The average power from a wind turbine (at a good site) is about 30% of peak, so a 2.5 Mw wind turbine average power output is 0.75 Mw. At 0.75 Mw per wind turbine it takes 1,333 wind turbines to put out the same power as a standard 1,000 Mw (nuclear or coal) baseload power plant!

In a recent article in Slate there is a brief mention of the effect of drastically lower lower natural gas prices on economics of wind turbines. The technical revolution of horizontal drilling combined with rock fracturing has caused US natural gas prices in the last four years to drop from $10 to $2. There is direct competition between energy sources in planning for electrical plants, so a x5 reduction in gas prices (if sustained) is huge. Gas plants are easy to build, don't need a lot of space or capital, but my understanding is a big gas plant does require a direct pipeline to gas wells."Boone Pickens, once of the wind sector’s biggest boosters, says wind projects need $6 natural gas to be competitive. Pickens also recently said “I’ve lost my ass” in the wind business." (Slate --- Obama’s Oil Blindness, by Robert Bryce, April 25, 2012)This smells like what happened in the years after the 1970's oil embargo when oil prices came way down and killed off the developing technologies of alternate energies. What congress should have done years ago is to put a floor, using taxes, under oil and gas prices that would keep alternate energies, like wind, viable. Instead it's being done with 'mandates', which are political and easily reversed when a new party comes to power.

Large 2.5 Mw wind turbines from different manuf are very similar, similar specs and in pictures they look almost the same. They have three thin (fiberglass/epoxy) blades, sweep out about 90 m dia (football field!), variable speed, variable pitch, actively pointed into the wind, on a tall (unguyed) steel tower (80 m). Two types of generators are in use (PM and double-fed asynchronous), and there is some variation in gear box design. One large wind turbine maker (Enercon) has long used no gearbox, instead coupling the blades directly to a very high torque, low speed generator. Northern Power, a maker of small (100 kw) direct drive turbines, has just introduced (2011) a large 2.3 Mw turbine also with no gearbox, and GE has one in development.

2.5 Mw wind turbines need about 10 m/s wind (22 mph) to output 2 Mw power. Amazingly (in the center of the power range) large wind turbines can capture about 50% of the energy in the wind that exists in an (imaginary) cylinder extending forward from the blades! Winds above 12.5 m/s (28 mph) have (far) more energy than the blades and electronics can handle, so from 12.5 m/sec (28 mph) and 25 m/sec (56 mph) the blades are slowly pitched (featured) to hold the turbine power at its rated power level.

The bigger the turbine the slower the rotation rate. The rotation period for Mw turbines is in the 3 to 6 sec range. In the center of the power range (wind speed 4 m/s to 10 m/s) the speed of the blades is controlled to increase linearly with the wind speed. The blade tip ratio (blade tip velocity to wind velocity) is controlled to be about 7 to give a high, stable angle of attack which results in good efficiency. This is why large turbines rotate slower. A larger radius for a specific m/sec air speed at the blade tip means a lower angular rotation rate (rad/sec).

Cut-in speed is 3 to 4 m/s and at about 12.5 m/s power hits max. In the upper half of the wind speed range (12.5 m/s to 25 m/s) the wind turbine runs at maximum power, shedding up to 90% of the available wind power at 25 m/s by adjusting the blade pitch and not allowing the rotation rate to increase. Above 25 m/s (56 mph) the wind turbines go off line with the blades feathered (80-90 degrees) for zero rotational force and brake locked. A fairly common survivable speed is 59.5 m/s (133 mph). Below cut-in wind speed, say 3 m/sec, no power is sent to the grid, but a small amount of power is generated by the blades, and it is used to accelerate the mass of the blades up to the minimum operational speed [3 m/sec (wind) x 7 (tip speed ratio) = 21 m/sec (tip speed)].

Enercon -- large wind turbines that are different50% efficiency mystery

For a long time the one exception to the similar large wind turbine rule were those made by Enercon (Germany). Their turbines have no gearbox. Instead they bolt directly to the blades a super high torque (> million ft-lbs!), very large dia ring shaped generator. Their turbines have a wider speed range (> 3:1) than others and results in higher efficiency (50%) over a wider range of mid-band speeds.Enercon is the largest wind turbine manuf in Germany (3rd world wide). They have been able to scale up their direct drive (gearless) design to a real monster, 7.5 Mw with 126 m dia rotor on a 42 story concrete tower that is now in production.

Power =

torque x angular speed

=

[radius x force] x angular speed

= [radius x (forward component of lift force)] x

blade rotation speed (in rad/sec)

While this may be satisfying to an aerodynamicist and (clearly) it provides accurate predictions of performance, it does not provide any intuitive explanation of how wind turbines really works. There is no (ground based) picture of how the air flows, of how it transfers so much of its wind kinetic energy to the occasional blade that slices through perpendicularly. Since the incoming wind loses half its wind kinetic energy to the blades, the air stream must be getting slowed down by the blades, but how exactly? The blade circle is 90-95% open, the air is coming by fast (10 m/sec, 33 ft/sec midband) and a narrow blade slices through about once a second, so why doesn't most of the air just pass through the blade circle without ever coming near a blade? I have searched and searched, emailed experts (one replied, "that's a good question"), and (as of Dec 2011) have found no answers.

The few papers on efficiency (not 'capacity' with which it is often confused) I find generally discuss the nearly century old Betz limit, which makes so many simplifying assumptions that I question how relevant it is to commercial wind turbines (see below). The widely quoted Betz limit of 59.3% provides only a crude limit as it is a very simplified one dimensional model constructed in the pre-computer era to be easily solvable. A recent paper that updates the Betz analysis by including radial flow terms calculates an efficiency of only 30%, which is clearly too low as this is far exceeded by real turbines.

Revised view of Betz modelEnergy payback time (update 6/14/11)

After spending considerable time to gain an understanding of the Betz flow model, I suspect it probably does provide a reasonably accurate picture of how the approaching air (assumed incompressible) flows through and around the blade area. It does not, however, provide any guidance at all about how the air flow interacts with the three turbine blades, because the betz model is bladeless. The Betz model just assumes a uniform pressure drop across (and near) the blade circle.Some references say the cause of the pressure drop in the Betz model can be thought of as being caused by a semi-permeable membrane (or series of membranes) that has resistance to flow. [Power = force x velocity], so flow forced though a resisting material would lose energy in the form of heat to the membrane(s). In fact the simple mathematical derivation in Wikipedia (Betz Limit) just shows a milk bottle shaped flow that widen as it slows. In the model a slowing flow is assumed, which implies energy is being lost, but the model and equations have no mechanism (zero, nada) to explain what causes the slow down or where the energy goes.

In real wind turbines power flows out of the generator, so the wind must be doing work (in physics 'work' is energy and is measured in joules) on the blades. If the Betz model applies to real wind turbines, which I think now it probably does, then the blades are probably making rotating pressure waves, which when averaged give the (simplified) uniform pressure drop the Betz model assumes.

A recent op-ed in the NYT (Gas Is Greener, by Robert, Bryce, 6/7/11) compared the amount of steel in wind turbines to gas turbine generators, saying it takes 200 tons of steel to build a 3-4 Mw wind turbine (or 50 tons/Mw), whereas a natural gas turbine built with 9 tons of steel will generate 43 Mw (or 1/4 ton/Mw). In other words a wind turbine he says requires x200 times more steel per Mw than gas turbine generators. He did not, however, not give the energy cost of the steel or the energy payback time.

A letter writer, who is writing a book to be called 'Harvest the Wind', responded that the energy payback time for wind turbines is only 7 months, saying "Wind turbines recover their full life-cycle energy inputs within the first seven months of operation". If true, this is good news. He also pointed out that Bryce did not count the steel required to build the pipelines to transport the gas. I did a little research to try and check this figure, clearly a good starting point would be to find the energy required to make a ton of steel. On my first search I found a confirmation. A steel industry webpage says a 3 Mw wind turbine in 20 years will output x80 times more energy than is used for its production and maintenance, referencing the Danish wind industry association (www.windpower.org). So the wind industry claims a very short energy payback time of only 3 months!

Check --- crude total payback time calculationWind's Future (my views, 2009)

Assume 2.5 Mw turbine, cost 5 million, 30% capacity (good site), and producer gets 10 cent/kwh (high). These are all optimistic numbers. (A 1.5 Mw Chinesee turbine that went up near boston cost 4.7 million.)2,500 kw x 0.30 capacity x 8,766 hr/yr x 0.10 dollar/kw = 657k/yr gross revenue (13.1% of cost)

Total payback time is 7.5 yr (not considering costs), more realistically probably something like 12-15 years and maybe 20 years with less optimistic numbers (sans subsidies).

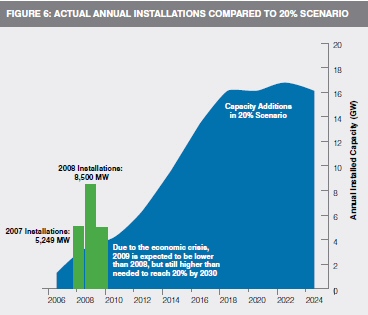

The goal of the wind industry (in most countries) is to grow to the point that it is supplying 20% to 30% of a country's electricity 10 to 20 years from now. USA goal is 20% by 2030 (http://www.20percentwind.org/). It looks doable. (Denmark has already reached 20% and Germany 8%.) To achieve this annual installations need only grow by x2 or x3 from current levels. The economics are also not that bad, probably a continuing (or declining) subsidy of 1/3rd of the cost, or put another way electricity from wind costs maybe x1.5 times more. That's pretty good for good clean renewable power, and far cheaper than solar.

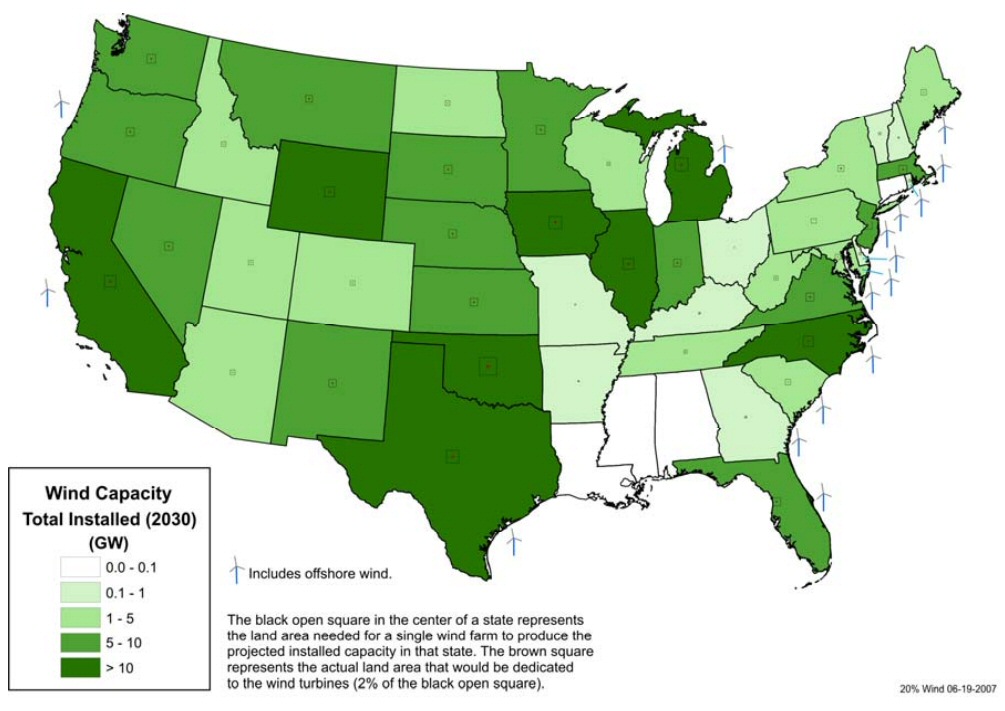

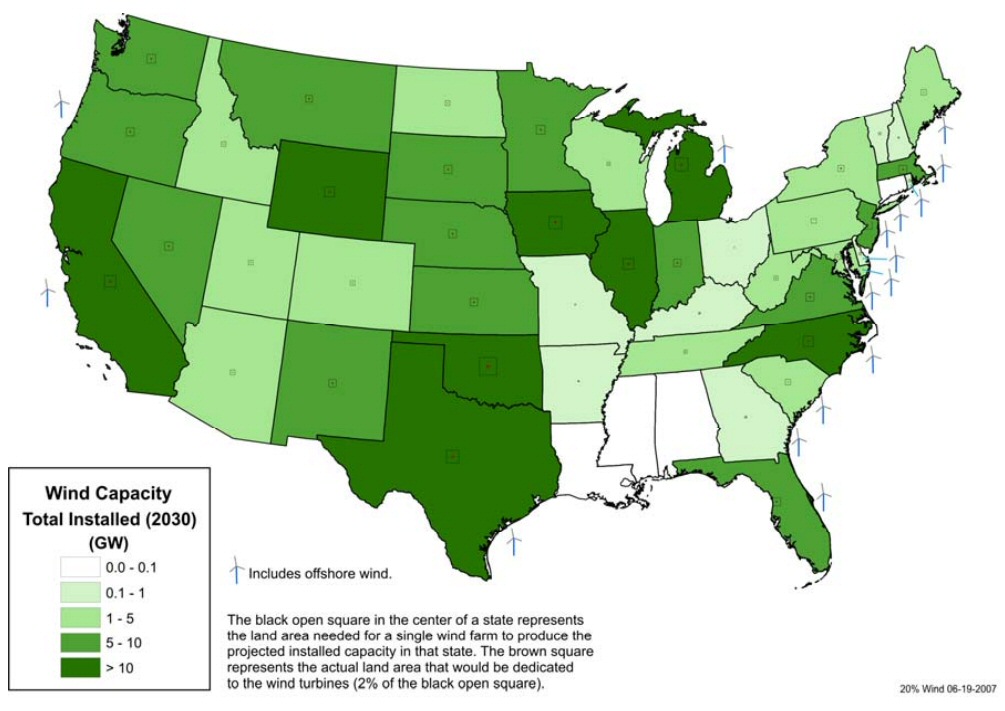

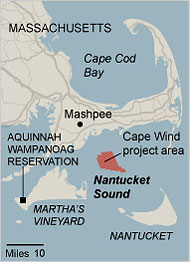

Here's a projection of the amount of land needed by wind turbine farms in each state in 2030 to meet the 20% of electricity goal. 18% of the country's wind power capacity is expected to be offshore, mostly on the east coast, where there is good wind and transmission costs are low, because the power is generated close to where it is needed.

Windpower king looks to be Oklahoma

Notice the land area in MA is almost same as TX!

(explanation is probably large offshore wind farms

in MA.)

source --- http://www.nrel.gov/docs/fy08osti/42794.pdf

Solar engineering is ten or twenty years behind wind. Thermal solar is still in the early prototype and small scale engineering stage and has not settled on architectures for production. Solar cells are further advanced than thermal solar and are at small/medium scale production, but costs remain far too high for full scale production.

(update Dec 2011)Whether there are enough good wind sites to support the tens of thousands of turbines that need to be installed, I have no idea. I see virtually nothing written about this in the general press. (Could be this is wind's dirty little secret?) A study by US Dept of energy shows that a good part of the midwest from Minn down to Texas has pretty good winds and a long strip of high wind sites runs down the Atlantic coast.

Reports are that silicon solar cells have declined greatly in price in the last couple of years, partly due to high Chinese production. I read (hard to believe) claims of a 90% cost reduction in the raw silicon cells.

2.5 Mw wind turbine cost

Turbine manufacturers

appear to sell 2.5 mw turbines for 3.0 to 4.1 million. [Clipper in 2008

sold 248 2.5 Mw turbines for 737 million, which is 3.0 million per turbine.

Another turbine manuf was paid 4.1 million per turbine.] [In 2008 T. Boone

Picken was reported paying GE 3 million each for 667 1.5 Mw turbines he

ordered.]

Cost installed can run 6 million for a 2.5 Mw turbine. Added costs include transportation, which I read can come to 20% of cost, plus installation (tower footing + crane to assemble turbine) and overhead. 6 million per 2.5 Mw turbine scales to about 8 billion for 1,000 Mw baseload plant equiv (1,333 turbines).

Hidden wind (& solar) cost (update 11/10)Introduction

It's slowly being recognized that there is a hidden cost associated with having a lot of wind power that is rarely mentioned in policy discussions. "At current penetration levels in California and parts of Europe have required substantial numbers of new gas power plants to fill in when the wind isn't blowing -- a cost which is typically not counted against the renewables." (From a long Slate discussion of climate and energy policy, Nov 18, 2010)While wind power can greatly reduce the amount of gas burned by these supplemental gas plants, it also means that a lot of capital is needed for plants with high peak power, but low average power.

One, I read that wind power costs have come down to the point where they are nearly cost competitive with fossil fuels. If this is really true it could be a real breakthrough, but is it true? Or does cost competitive mean cost competitive only when taxpayer subsidies are included? [Well, it's the latter of course!]

Second, I saw a picture of men standing on top of a wind turbine and from this perspective I realized how truly enormous wind turbines have become.

Third, I saw a TV show about the adventures of a fleet of trucks hauling monster loads up to South Dakota, which I later realized were a blade and tower segments of a huge wind turbine, I also read (in the New Yorker I think) about a small Texas town in oil country that has become one of the wind centers in the US with wind farms all around the town and wind offices downtown. [Roscoe Wind Farm in Roscoe, Texas is the world's largest wind farm (as of October 2009) with 627 wind turbines and a total installed capacity of 781.5 Mw, and nearby is Horse Hollow farm in TX with an additional 735.5 Mw.]

Fourth, as a motor control and power engineer I'm interested in the electrical technology. In the very early days of wind (early 1980's) as part of my job I read some papers about wind electronics, but nothing since. In the early days the few wind researchers around were exploring how to best couple power from a blade driven wind turbine to the electrical grid. This is a non-trivial problem, and one of the two or three core technologies of a wind turbine. It is tricky because the blade frequency is variable while the line frequency is fixed, and also the power levels vary widely. At the time this was an unsolved problem, but looking at the hundreds of big wind turbines now installed, it is clear one (or more) solutions to the electrical problem have been found. How is it being done I wondered?

Not baseload power

Power is power,

but wind along with solar has a big disadvantage in that its variable and

worse it's not predictable. The power comes and goes (with the wind!).

Some degree of averaging might be possible with many wind farms spread

out across a state, but I have not seen any info on how significant this

might be. Unless some local storage technology is developed (liked pumped

air underground) wind will be a supplemental power source to baseload plants

like coal, nuclear and hydroelectric. Denmark and northern Germany now

generate 20% of their electricity from wind, so intermittency at 20% penetration

is clearly manageable.

[wind turbines + gas plants]Capacity

There are reports that wind power is being paired up with new gas plants designed for high peak to continuous duty. To smooth out the variable wind power what is needed is a power plant that is fast responding, requires the minimum of capital to build, and relatively high fuel costs can be tolerated. Apparently specially designed gas plants serve this need. (A NYT oped pointed out they require x200 less steel/Mw than wind turbines.)It is an interesting to think in terms of [wind turbines + gas plants] as baseload (continuous power) power plants. Politically it's obvious why this barely gets mentioned. Wind looks a lot less 'green' when it is admitted that it needs to be paired up with fossil fuel burning plants to be a reliable source of electrical power!

For comparison the capacity of solar in the southwestern desert is about 25%, meaning the it runs equivalently at full power six hours a day. Univ of MA says solar capacity in Massachusetts is 12% to 15%, or about half of what it would be in a southwestern desert. The lower value in MA is due to clouds and lower angle of the sun in the sky compared to AZ. The capacity of nuclear plants is 92% (national average).

Power vs wind speed

[Power =

torque x speed] with the torque load on fan blades going as the square

of speed. This means the power of the wind increases very strongly (as

the cube!) with wind speed. This basic character of wind power is extremely

important. It means there is a very big payoff to getting the high (steady)

wind speeds. The only practical siting for grid power wind farms is in

the most windy locations and on high towers.

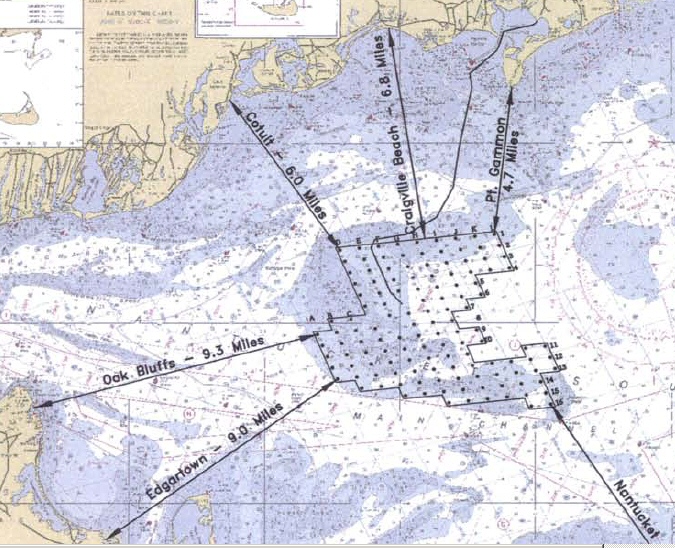

For large turbines (2.5 Mw and up) a good rule of thumb is that pretty steady winds of 20 mph (9 m/s) are needed. (Cape Wind monitored the wind for three years at their offshore site in Nantucket where they plan to site 3.6 Mw turbines and report it to be 19.75 mph average.)

Storms

A critical

issue with wind turbines is the ability to survive high wind storms. In

the early days I remember reading an article saying wind turbines (and

wave turbines) would never be practical, because come a big storm they

will all go down. This argument was based on the huge increase in torque

load on the blades vs wind speed. There was hard evidence supporting this

position too, as the few large wind turbines built in early days virtually

all did blow down after a few years of operation (or they failed from fatigue).

I was glad to see a survivable wind speed spec on the large Nordex turbine (however I see no survivable wind speed spec on the GE or Clipper turbines!) , and it seems to reference an IEC standard, which is a good thing because it means there are standardized test conditions.

Nordex 2.5 Mw survivable wind speed spec 70 m/s (156 mph)

Nordex has a second model with slightly (13%) longer blades on a slightly higher tower, which allows it to put out out 25% to 30% more power at lower wind speeds. It reaches its maximum output power (2.3 Mw) at about 27 mph (vs 31.3 mph). The longer blades lower the survivable wind speed of this model from 156 mph to 133 mph.

Blades on large turbines have variable pitch, so the approach to storms is to take the turbine off line (> 25 m/s) and pitch the blade for zero net torque (effectively to balance the forces on both sides) to stop rotation. There are also brakes in at least some of the large turbines. Clearly the tower and its mount need to be strong enough to absorb the axial forces on the blades. Also the axle holding the blades needs to be strong enough to absorb the bending force from different top/bottom wind speeds.

This bring up a minor puzzle. Notice in the gallery below the Nordex being assembled. There is no (long) axle sticking out of the nacelle onto which to mount the blades! How is the blade hub attached to the nacelle? Are they just bolted together? While it's hard to see, the rumpy little axle projecting from the nacelle looks awfully wimpy.

Types of wind turbines

The Nordex

(see picture) is the most common type I see in pictures. Technically the

type is horizontal shaft, into the wind, with three blades. This type must

be actively turned into the wind with a yaw motor and control (as opposed

to a downwind type, which self adjusts like a weather vane).

Theory

Principle of operation

The basic

mechanism underlying the operation of most wind turbines is rather subtle

and hard to understand intuitively. (I had little understanding of it until

I worked on this essay.) The same principle explains why kites do loops

and whirls, why glider airplanes fly, and why wind turbines can extract

energy from the wind.

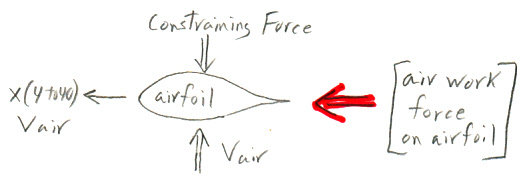

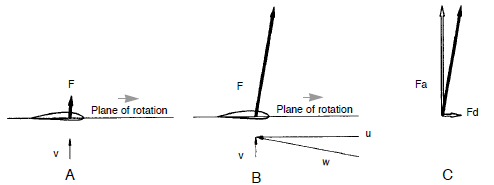

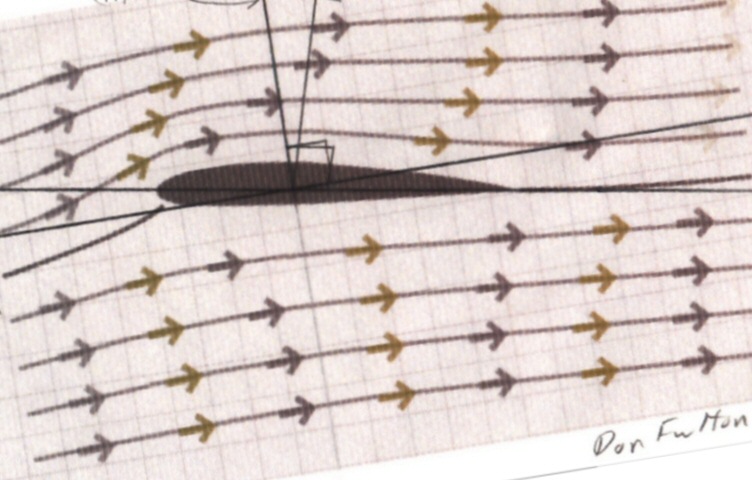

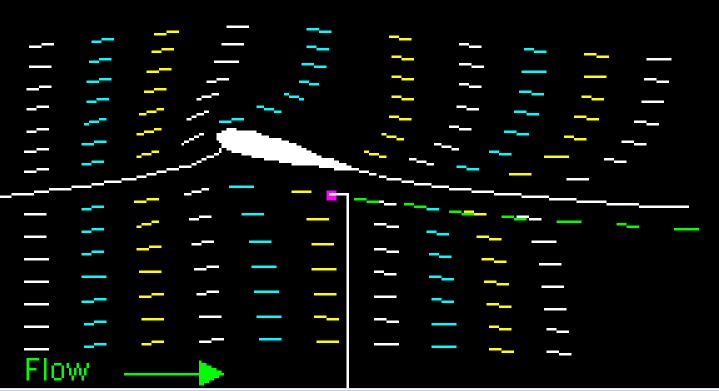

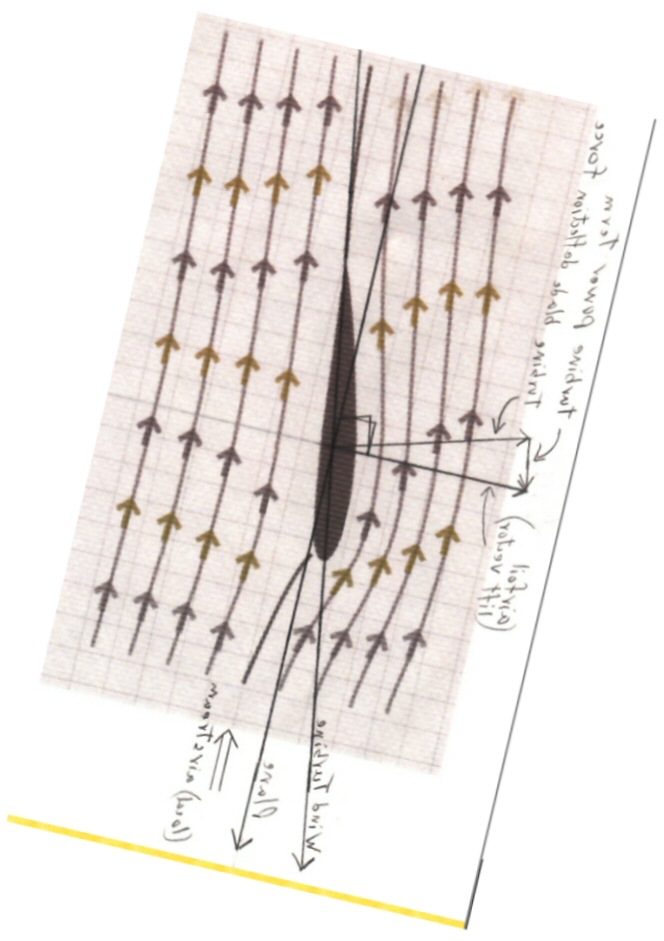

Perpendicular motion through an airstream

Consider an airfoil placed in a mass of moving air, oriented exactly flat to the air flow. Constrain the airfoil such that it cannot move in the direction of the air flow, but is free to move perpendicular to the air flow.If the airfoil gets moving several times faster (x4 to x40) than the air, then (surprisingly) some of the force of the air on the airfoil points in its forward direction of motion, perpendicular to the air flow direction. Since [Energy = Force x Distance], this means the moving air does work on the airfoil. The energy received by the airfoil comes from the kinetic energy of the moving air, whose air flow speed is reduced by the encounter. (below my little sketch of the motion and forces)

Symmetrical airfoil moving fast perpendicular to wind extracts energy from the wind

due to a force (red arrow) from the air flowing around it pushing in the direction of motion.

This force is usually described as a component of the 'lift' force of the airfoil.

The basic mechanism generating the forward force on the airfoil is a region of lowed dynamic air pressure on its upper (back) front surface. Some of the air the moving airfoil encounters speeds up to flow up and over the back side of the airfoil (losing energy), while air hitting the underside of the airfoil is reflected back making a region of increased pressure. This force is usually described as a (forward leaning) component of the 'lift' force of the airfoil.Wind power equationSpeed ratios

In a wind turbine the tip of the blade is typically moving x7 the (wind) air speed, so angle of attack is [tan^-1 (1/7) = 8.1 degrees]. Glider planes need to extract only a little energy from the 'wind' (decrease in height/sec) to keep flying, so they are able to operate at much lower angles of attack giving them airspeeds of x40 the fall rate [tan^-1 (1/40) = 1.4 degrees].

Pout = [power coefficient] x Pwind

Pwind = [1/2 x air density] x [area swept out by the blades] x [air speed^3]

= [1/2 x rho]

x

[(pi/4 x D^2]

x v^3

where

rho = density of air [1.275 kg/m3] (Wikipedia, 'air density')

D = dia of area swept out by blades (m)

v = velocity of air (m/sec)

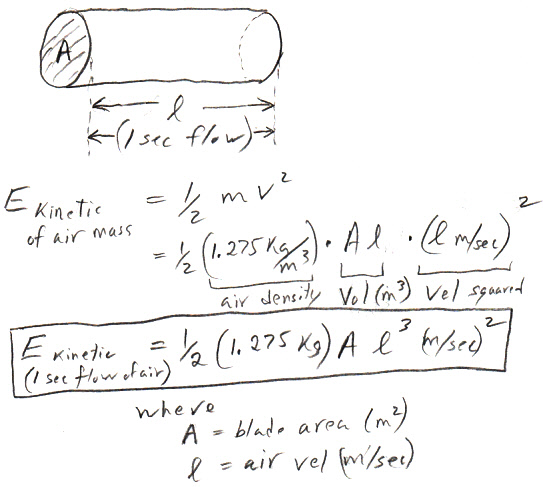

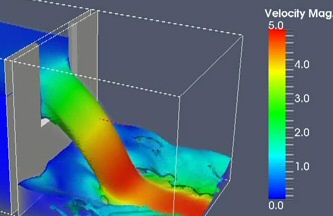

Wind energy equation from air energy

As a check of the

equation for Pwind above, which I find in the literature, I made the sketch

below. It shows the kinetic energy (@ wind drift speed) of cylinder of

air that moves through the blade circle in one second. It shows the (1/2)

is included. It also 'exlains' why the power in wind goes as wind velocity

cubed. The reason is that the kinetic energy in air per unit volume goes

as vel^2 and the length of the air cylinder is proportional to vel, hence

the (air) energy flow per second through the blade area goes as vel^3.

my little sketch of energy in air cylinder

(idealized flow --- ignores fringing)

Let's put in some numbers to check the air mass

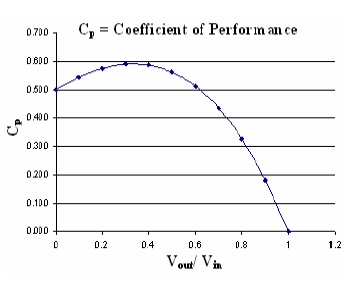

Assume 2.0 Mw Enercon E82 with blade diameter of 82 m (270 ft). It performance

curves show this turbine although nominally a 2.0 Mw turbine typically

outputs 2.1 Mw (@ 12 m/sec). At 10 m/sec its output power is 1.6 Mw and

at this wind speed the curves shows its power factor is just a hair under

50% (about 49.5%). The Enercon curve (below) shows the power coefficient

peaks (51%) somewhat a little above mid band near the inflection point

in the curve.

Mass of air (1 sec) = rho x A x length

= 1.275 kg/m^3 x (3.14/4) x (82 m)^2 x 10 m

= 62,300 kg

Wow, 62,300 kg (148,000 lb or 74 tons) of air will pass through the blade circle per second

Air energy check for 1.6 Mw from 2 Mw Enercon turbine

at v = 10 m/s

P wind = 1/2 rho x (Area) x v^3

= 1/2 x 1.275 kg/m^3 x [5,278 m^2] x (10 m/s)^3

= 3.365 Mw

1.6 Mw /3.365 Mw = 47.5%

vs 49.5% (curve)

checks

--------------------------------

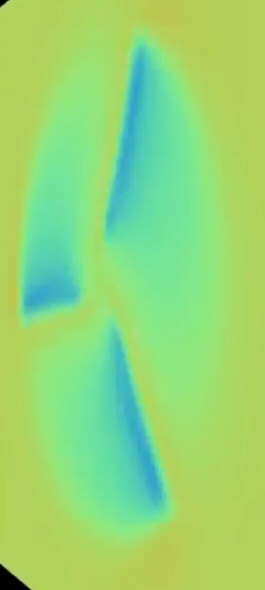

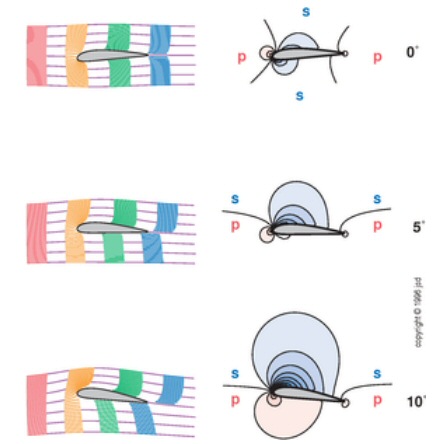

Efficiency vs tip speed ratio

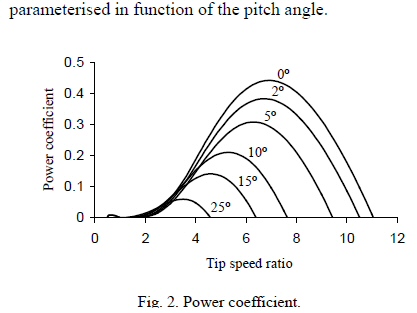

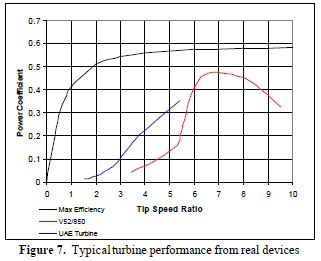

The figures

below (from two papers) show how power output from a large variable speed,

variable pitch wind turbine varies (at least in principle) as the blade

speed is varied (relative to the wind) and the blade is rotated (degrees

from flat to the wind). There's a clear maximum at a tip speed ratio of

about 7 (6 to 8) and 0 degrees pitch, so this the operating point nearly

all large wind turbines hold at mid-band wind speeds.

A power coefficient of 0.45 agrees very nicely with the curve below from the above paper (link below), which shows a maximum of about 0.46. Enercon plots the power coefficient with their power vs speed curve and it shows a midpower peak of 0.50.

Tip speed ratio is the ratio of blade tip speed to

wind speed

from unpublished Portuguese paper

http://www.aedie.org/9CHLIE-paper-send/296-MELICIO.pdf

Curve below (in red) from a slightly smaller turbine (850 kw, three bladed, 52 m dia, probably a different manuf) is remarkably similar. Same 46% peak efficiency for tip speed ratio of 6 to 8.

http://www.caspus.eclipse.co.uk/ah/publications/3dmwtucfd.pdf

(blue is an experimental two bladed turbine)

(black is modified Betz Limit)

These papers made no mention of why power should peak near a tip speed ratio of 7, but later when I came to understand the basics of the rather peculiar aerodynamics of wind turbine blades, the tradeoffs (at least qualitatively) began to make some sense. The short explanation from aerodynamics of the blade/airfoil is that power output initially grows as blades rotate faster due to growing forward pointing component of lift force (torque force), but somewhere around a tip speed ratio of 7 where the outer blade is moving at 154 mph improvements in lift begin to be overwhelmed by higher drag, so the curve rolls off. I discuss this matter in more detail (section on blades) later in the essay.

Checking tip speed ratio

It looks like there's an inflection point in the Clipper power curve at

about 2.2 Mw so I'll guess the blade speed hits its maximum [15.5 rpm]

at this power. (For higher wind speeds power would still rise, but

efficiency would begin to fall off.) Since blade speed is proportional

to wind speed at mid power, at 2 Mw (10 m/s wind) the blade speed would

be about [0.9 x 15.5 rpm] = 14 rpm with a period of 60 s/14 rpm = 4.3 sec.

Figuring the circumference from the swept area (blade length doesn't work

because it does not include hub). The ratio of [circumference/sqrt{area}]

is

[circumference/sqrt{area}] = 2 pi R/sqrt{pi R^2} = 2 sqrt{pi} = 3.54

circumference = 3.54 sqrt{area}

tip velocity = circumference/period

= 3.54 sqrt{7,854 m^2}/4.30 sec

= 314 m/4.3 sec

= 73 m/s (@ 10 m/s wind speed)

tip speed ratio = tip velocity/wind velocity

= 73 m/s/10 m/s

= 7.3

check

Tip speed ratio

Tip speed ratio

[tip velocity/wind velocity] = 7.3 agrees very nicely with the curve above.

Keeping the tip velocity 6 to 8 times the wind speed (for this type of

turbine) maximizes the efficiency of the power transfer from wind to blades

(about 45%). Enercon blade patent 6,899,523 (here)

confirms that the blade speed is varied linearly with wind speed.

Since mid-band speed is about 10 m/s for large wind turbines, a tip speed ratio implies the tip speed is about 73 m/sec (in almost all large turbines). In fact Spanish Acciona wind turbines spec the tip speed in their two large turbines: 74.7 m/s at 13.2 rpm (3 Mw) and 73.9 m/s at 18.3 rpm (1.5 Mw).

Another confirmation of tip speed ratio is below. Where possible I have calculated the tip speed ratio (@ 10 m/sec) from the wind turbine specs. In all cases I get between 6 and 7.3 (This is just an estimate as the rotation period at 10 m/sec must be guessed at, extrapolating from the turbine rpm range and the turbine power rating.)

What's the deal with tip speed ratio?

What's

I first saw that wind turbines were characterized in terms of 'tip speed

ratio', and its value always seemed to be near 7, it seemed kind of mysterious.

Rotational air speed varies along the blade, so it was not all clear to

me why tip speed ratio should be a key parameter, nor why it should be

set at 7.

The overview picture is probably something like this. The aerodynamics of blade/airfoils shows the power output initially grows as blades rotate faster due to growing forward pointing component of lift force (torque force), but somewhere around a tip speed ratio of 7, where the outer blade is moving at 154 mph (70 m/sec for 10 m/sec wind) improvements in lift begin to be overwhelmed by higher drag, so the curve rolls off.

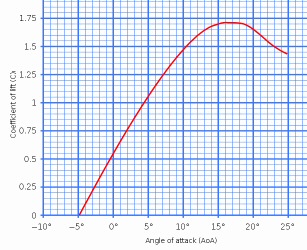

The lift equation for airfoils shows the magnitude of the lift force increases as the square of the (relative) speed between the airstream and the airfoil, but a turbine vector wind diagram shows that as the blades rotate faster the airstream hits the blade at a flatter angles, so the lift force vector, which is perpendicular to the airstream, has less forward lean. The result is that the fraction of the lift force that produces torque keeps getting smaller (as blade speed increases), while at the same time as the magnitude of the lift force is getting bigger. Since lift force is increasing as the square of speed, it dominates and the forward (torque producing) component of lift increases with speed. But drag must be increasing with airspeed too, and the peak of the power coefficient curve is probably the tip speed ratio where increases in drag begin to exceed increases in forward lift force.

There's also the issue of angle of attack. At a tip speed ratio of 7 (airspeed of 70 m/sec for wind of 10 m/sec) a vector wind diagram shows the incoming air approaching the blade at an angle of tan^-1(1/7) = 8.1 degree. This means the lift vector is tipped forward by 8.1 degrees, so about 1/7th of the lift force [sin (8.1) x lift force] is pointing in the direction of blade motion and creating power. This puts the angle of attack for the flat oriented outer blade right in the middle of the 0 to 15 degree (useful) range, and it gives it room to rise in the lower and mid regions of the blade, where wind speeds are lower, and yet remain in the useful range so the these blade regions operate efficiently. Hence at a tip speed ratio of 7 the working part of the blade (outer 3/4th) ends up operating with good angles of attack between 8 to 15 (when blade twist is taken into account down near the hub), so each part of the blade generates good lift for the air speed it sees.

Are gliders the key?

The key may be to

look at how gliders are designed. High performance gliders typically fly

100 to 150 mph. The outer parts of wind turbine blades look like glider

blades and work like glider blades. With a tip speed ratio of 7 airspeed

near the tip is 70 m/sec or 154 mph, near the maximum for gliders. A tip

speed ratio of 14 would mean airspeed over 300 mph. If this speed is too

high for gliders, for the same reason (probably drag) it's probably too

high for wind turbines. Too much drag, which in a glider translates to

poor range, in a wind turbine translates to low efficiency.

Energy transfer puzzle

If you consider

the energy transfer between air and airfoil (wing or blade), there is a

big difference between wind turbines and airplanes. The difference is this:

the direction of the energy transfer between air and airfoil is

different in a wind turbine than in an airplane. At first (and 2nd) glance

this is very puzzling because wind turbine blades are essentially rotating

wings and are described by the same lift equation as in airplanes.

An airplane clearly (?) transfers energy from the airfoil (wing) to the air. A plane flying through still air leaves behind a contrail of moving and swirling air, air that clearly has gained kinetic energy. We can see in wing air flow diagrams that air flowing over the top surface of a wing is clearly accelerated in the opposite direction of the planes travel. It seem obvious that the source of the energy imparted to the air comes from the planes engines. In the case of a glider, which I presume leaves a weak contrail, it too has an available source of energy from its loss of potential energy as it descends closer to the center of the earth.

However, NASA emphasizes in its airfoil simulations that an airplane stays aloft because the wind deflects the air downward. Is it possible that the kinetic energy of the contrail air comes from its loss of potential energy not from the plane's engines?In a wind turbine the air-airfoil energy transfer goes the other way, energy (lots of it) transfers from the air to the airfoil. The whole point of a wind turbine is for its rotating blades to extract large amounts of energy from the moving air.

At this point I don't have a good explanation for this difference. I presume that like many problems in mechanics the approach is work out the motions due to forces and inertias, and only then can the energy transfer be calculated. The energy transfers don't dominate, they only need be consistent [energy in = energy out]. It's not hard to think of physics textbook problems where energy transfers seems surprising. One that comes to mind is the row of balls hanging on strings lined up in a row and touching. When a swinging ball hits one end, it stops dead and the ball at the other end flys off. A total transfer of energy from the 1st ball, through many stationary balls, to the nth ball. It's so intuitively surprising that you find this little toy on lots of people's desks.

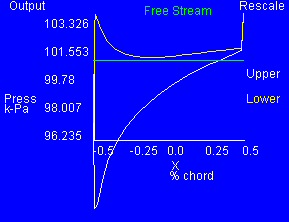

High wind speed operation

Notice from

the power out vs wind speed curve below (for Clipper) the wind turbine

power maxes out at 2.5 Mw about 12.5 m/s wind speed, but remains operational

(with 2.5 Mw out) as wind speed doubles to 25 m/s. A doubling of wind speed

increase the Pwind x8. There's no way they can allow the blades to pick

up x8 more power because it can't be processed to the line so it would

have to be dumped as heat. Hence the blade pitch and speed need to be adjusted

for a 1/8th lower power coefficient.

The power coefficient curve above indicates how this is probably done. As wind speed doubles from 12.5 m/s to 25 m/s the blade rotation speed is probably kept constant, which lowers [tip speed/wind speed] by a factor of two to about 3 to 4, and the blade pitch is increased to 25 degrees, meaning the blades are rotated so they don't intercept as much air. The curve the shows the power coefficient drops the required factor of 8 to about 0.425/8 = 0.05.

Blade design for high speed survival?

My speculation

(as I write I have seen nothing on this):

I suspect the blades and generator are hard connected together (thru gearbox) and survival of high winds (> 25 m/s) depends on blade design. In pictures of the blades show a substantial twist. It might be that if the blade pitch is high enough the net rotation torque goes to zero. Essentially there would be equal forces from the air on both sides of the blade. This should be clean. Upon switching into the shutdown mode the pitch is increased and the blades probably coast toward zero even with the electronic loading removed, and the mass of the blades would handle transient wind direction changes. [This is right. One manuf says the brakes are applied too, probably only when the speed gets near zero.]

Theoretical

wind turbine efficiency analysis is sketchy

(Update --

The section that follow is my original write up on the Betz Limit, before

I really understood what it implied about the air flow. Following find

'Betz Limit decoded' and 'Understanding the Betz Limit' that reflect my

new views of the Betz model. I now suspect for a simple model the Betz

model is probably pretty good, that it provides a pretty good picture of

of how wind turbines work and reasonable ballpark numbers for air speeds

and wind turbine efficiency.

-----------------------

I read the

Betz Limit, described as the maximum fraction of power which can be extracted

from a moving fluid by a turbine, was 59.3%. This seemed simple and looked

consistent with the 46% efficiency that large turbines were actually achieving,

but upon further reading it's not at all this simple. In fact as of 2009

it appears that no one in the public domain seems to have a clue as to

how to calculate accurately the efficiency of a wind turbine! (In

part because this is because public domain data on blade lift coefficients

and power cofficient vs tip speed ratio is sketchy.)

The Betz model was formulated in precomputer days (1915) and is a very simple one dimensional model, so flow direction changes are ignored. It does not use blades, it uses a thin permeable disk covering the entire area swept out that allows flow through it and extracts some energy from the flow as it passes through. The pressure across the whole disk is assumed uniform. It also looks like there are walls constraining the flow, so the air does does not have the option of going around the high pressure disk area. Does this really apply to a blade system in free flow? Seems pretty unrealistic to me.

In 2001 a Russian and Northeastern guy (Gorban and Gorlov) allow for free flow and account for two missing terms in the Betz model, and they calculate a maximum efficiency of only 30%, only about half the Betz Limit of 59.3%! This is clearly too low since real turbines measure much higher than this (about 46%)! A 2008 paper reviews the all the literature and the best they can do is give experimental results from a medium size turbine that also shows a peak efficiency of 46%.

http://en.wikipedia.org/wiki/Betz_limit

http://www.caspus.eclipse.co.uk/ah/publications/3dmwtucfd.pdf

Wind energy is the total kinetic energy of all its air molecules each with (1/2 m v^2). Power varies as the cube of speed, because double speed increases by x4 the kinetic energy of each air molecules and twice as many air molecules per second flow by. If in a wind turbine you try and all pull all the kinetic energy from air molecules, they obviously no longer flow (v = 0) so (in some sense) they pile up and block the flow. Your continuous power out will fall to zero. If a wind turbine is extracting 46% of the (wind) kinetic energy of the air molecules, it must mean 10 m/s wind going in becomes 7.3 m/s wind coming out (& its area expands 37%), because [1 - 0.73^2 = 0.46].

Betz Limit

The basic power in wind (simplified) is below, where [v = velocity of wind]:Pwind = k x v^3

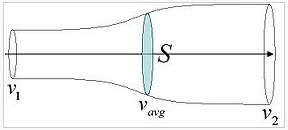

Wikipedia ('Betz Law') shows the Betz model yields the equation below for extractable power from a moving fluid, where (see Wikipedia figure below) v1 is air velocity in and v2 is air velocity out and v = [(v1 + v2)/2] the average air flow at the turbine.

Pout = k x v (v1^2 - v2^2)

Pout = k x (1/2)(v1 +v2) (v1^2 - v2^2)

source --- Wikipedia 'Betz Law'Subtle trap?Above equation has a simple interpretation. It is the difference in kinetic energy of air molecules entering and leaving [(v1^2 - v2^2)] x average flow through the turbine [(1/2)(v1 +v2)]. Thus the ratio of wind power than can be extracted is:

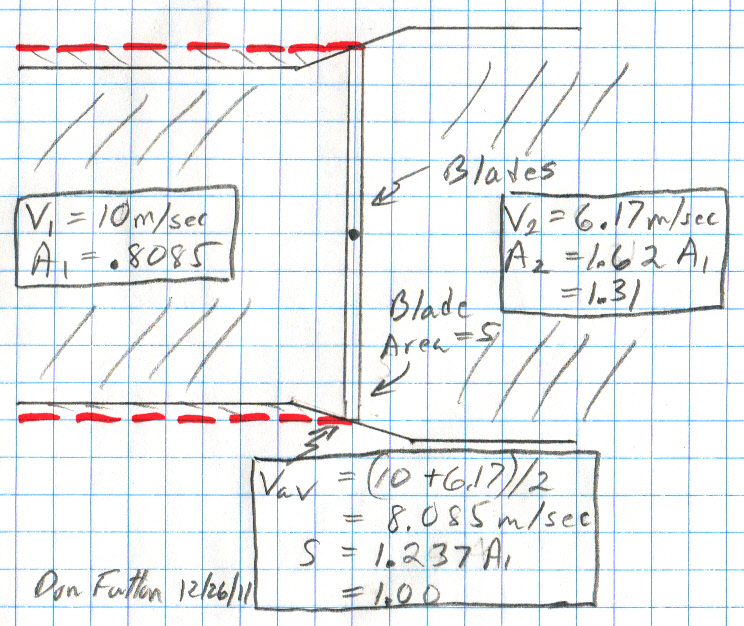

Obviously the air mass flowing in and out had to be the same, but the out flowing air (having lost lost kinetic energy) is moving more slowly, so for the same mass (per second) to pass the area of the flow cylinder has to expand as the air slows. The product [vel x area] is a constant, so area expanding inversely to the velocity. At the betz peak efficiency ouput speed V2 is only 33.3% of V1, so the ouput area A2 has expanded to x3 input area A1.I agree with the Wikipedia derivation of the above equation, but there's a subtle point here, a possible trap. As the figure clearly shows the area of the turbine blades (S in figure) is not the same as the area of the input cylinder area. The cylinder is shown expanding as the air slows and the turbine is positioned (sort of) midway at the point where v (average) = (v1 + v2)/2.

If a wind turbine is extracting 50% of the kinetic energy of the incoming wind, then the out flowing air must be moving about 29% slower (v2 = .707 x v1), which means the area of the output cylinder must be x1.41 larger (radius increase of 18.9%).

Pout/Pwind = k x (1/2)(v1 +v2) (v1^2 - v2^2)/k x v1^3

= (1/2) (v1 +v2) (v1^2 - v2^2))/ v1^3

= (1/2) [ 1 + (v2/v1) - (v2/v1)^2 - (v2/v1)^3] Betz equationPlotting the equation above we get the Betz curve:

A hint that this model is a little strange is the value at the origin of 50%. On the one hand with [v2 = 0] it appears that all the wind's kinetic energy has been captured, so the recovered fraction of power should be 100%. On the other hand with an output wind velocity of zero, isn't the air just going to 'pile up' and there will be no flow? (Well, the math answer is that the output area has expanded to infinity!) The Betz model generates 50% because the energy term gives 100%, but the average flow (average of 1 and 0) is 1/2. No velocity for the output wind is a weird condition, and the 50% value here is a strong hint the model is not valid at low output wind speeds.What does the betz limit mean?The peak at [v2/v1 = .333] kept bothering me. This means the output wind has only 11% of its kinetic energy remaining! So why isn't the efficiency 89%? The answer is the Pout/Pwind has the pesky term [(1/2) (v1 + v2)], which derives from the turbine area not being the input area but the area of the cylinder where the velocity is average. The value of this term is [1/2 x (1 + .333)] = .666, and (.666 x .889) = 59.3%. Another indication that the betz limit is rather strange.

It took me

a while to figure this out, to really understand the betz model and to

what extend it applies to wind turbines. When I read the long discussion

page of the Wikipedia 'Betz Limit', I found a lot of other people were

bothered too, and I found various takes on the limit. I think I now understand

what the betz limit means.

-----------------------

Betz limit decoded

(1/2/12

update)

The Wikipedia

'Betz Limit' I found had a pretty clean, simple derivation of the Betz

Limit (I later improved it), but no explanation as to the puzzling Betz

results. After thinking about this for a few days, I finally figured out

what was going on --- upstream air as it approaches the blades and expands

forces a ring of air, included in the reference cyclinder, radially outward

such that it bypasses the blades and contributes no power to the

turbine. Nowhere had I ever seen this explained, so I wrote it up and added

it to Wikipedia article 'Betz Limit'.

Key idea

The Betz model

in its efficiency calculation uses for a reference (reasonably) a cylinder

with the area of the blades, but the model shows area of the flow downstream

is smaller than the blade area. According to the model the flow

as it approaches the blades and begins to lose energy expands to exactly

the

area of the blades as it passes through the blades. My insight was

that the expanding air flow shown in the Betz 'milk bottle' flow diagram

must be pushing radially outward a ring of air that surround it! And because

the flow expands to exactly the area of the blades upon passing through

the blades, some of the air in the input cylinder that would be expected

for straight axial flow to hit near the tips of the blades must be bypassing

the blades.

Some of the upstream air bypassing the blades explains why the Betz results (at all speed ratios) show a lower efficiency than would be predicted from the speed ratio! Conversely, it means the downstream air always has slowed more than a simple calculation using Cp (wind turbine efficiency) would predict. I had been assuming that because modern turbines are about 50% efficient (using a cylinder of blade area for power reference), that it was intrinsically obvious that the speed of the downstream air must be .707 of upstream air. Nope, the Betz equations and picture say no, the air exiting the turbine blades slows more than this. For example, at the Betz Limit of 59.3% a simple velocity interpretation would say the air had been slowed to .638 of incoming speed, but the Betz equations say the speed ratio for 59.3% efficiency is only .333, which means air that actually passes through the blades (as opposed to bypassing the blades) has lost 88.9% of its kinetic energy.

From this point of view the 50% mystery is worse! When only air that actually passes through the blades is considered, wind turbine blades are even more efficient than 50%! Below I do a calculation for modern 50% efficient turbines that shows at least 61.9% of the kinetic energy of the passing through air is extracted by the blades.

Understanding the Betz results (12/29/11 addition to Wikipedia 'Betz Limit' by me)

The Betz results are at first glance a little hard to understand. For example, why is the maximum Betz efficiency 59.3%, when a speed ratio of [V2/V1 = .333] implies the air passing through the rotor has lost 88.9 % of its kinetic energy? The left side of the betz curve shows a maximum efficiency of 50% when the exiting air (V2) has no axial velocity. Is this realistic?

The answer to the second question is easy. 50% efficiency at [V2 = 0] is not realistic, the model breaks down at very low exit speeds. The Betz model assumes a constant density fluid and that implies the cross sectional area of the flow varies inversely with axial speed. At [V2 = 0] the cross sectional area is infinite! Mathematically the exiting air does not 'pile up' because it is spreading radially, but radial kinetic energies are not accounted for in the Betz model.

To show that 59.3% Betz efficiency is indeed consistent with a loss of 88.9% of kinetic energy in the air passing through the rotor a physical picture is helpful. The equations for power extracted from the air flow apply to the 'milk bottle' shaped flow shown in the figure at the beginning of this article. The upstream flow (V1) has a cross sectional area less than the rotor area (S). As the flow approaches the rotor, it begins to lose energy, and as it passes through the rotor the equations show it expands to exactly the rotor area (S).

The last step in calculating the Betz efficiency (Cp) is to divide the calculated power extracted from the flow by a reference power value. The Betz analysis uses for its power reference, reasonably, the power of air upstream moving at V1 contained in a cylinder with the cross sectional area of the rotor (S).

The key to understanding why the Betz limit is lower than implied by the speed ratio is to understand that some of the air in the Betz reference cylinder does not pass through the rotor. The area of the flow that will pass through the rotor is upstream smaller than the rotor area. It expands to the rotor area as it reaches the rotor, implying that roughly half the energy transfer from the air to the rotor occurs before passage through the rotor. Thus it must be the case that the air just outside the flow gets pushed radially outward as the rotor is approached just enough so that it bypasses the rotor. The Betz equations do not include any terms for air that bypasses the rotor, its contribution to the extracted power is assumed to be zero.

As a check, let's calculate conditions at the Betz limit: 59.3% efficiency at [V2/V1 = .333]. The equations show the flow speed at the rotor is the (arithmetic) average of V1 and V2, or [V1 (1 + .333)/2 = .666 V1]. For constant density fluid the product of the speed and area are constant everywhere along the flow, so [V1 x A1 =.666 V1 x S], where A1 is the area of the flow upstream at V1. Thus A1/S = .666, meaning only 2/3 of the air in the upstream reference cylinder will eventually pass through the rotor and contribute to the extracted power. Thus the denominator in the Betz efficiency calculation is (in effect) inflated by 3/2, so the efficiency based on speed changes (88.9%) must be scaled by inverse of 3/2, or 2/3. [88.9% x .666 = 59.3%] gives us the Betz limit. Checks.I also added to the 'Betz Limit' in Wikipedia at about the same time the section below on the efficiency of modern large wind turbines, with a footnote to Enercon whose data sheets I found has plots of Cp for its whole family of turbines. I also added an equation for Pwind that explicitly showed the power in the reference input cylinder of air (which much earlier I had derived), and I added a sentence under the milk bottle figure that area 'varies inversely with speed'.

A couple of day later (1/3/12) I realized the Betz curve tells us more than the maximum theoretical efficiency. If the Betz model is correct in implying that a (calculable) fraction of the reference air bypasses the blades, then it can be used to estimate the downstream wind speed of real turbines, so I added to my Wikipedia edit the paragraph below.Modern large wind turbines achieve peak values for Cp in the range of 0.45 to 0.50, [4] about 75% to 85% of the theoretically possible maximum. In high wind speed where the turbine is operating at its rated power the turbine rotates (pitches) its blades to lower Cp to protect itself from damage. The power in the wind increases by a factor of 8 from 12.5 to 25 m/sec, so Cp must fall accordingly, getting as low as 0.06 for winds of 25 m/sec.footnote [4] -- "Enercon E-family, 330 Kw to 7.5 Mw, Wind Turbine Specification" (pdf), links to below

http://www.enercon.de/p/downloads/EN_Productoverview_0710.pdf

The Betz model can also be used to estimate the downstream air speed of real wind turbines. Kinetic energy of wind depends on speed squared, so if a modern large wind turbine is extracting half the wind's energy, which is possible, then from energy considerations it would seem that the downstream air speed (V2) should be x.707 of the upstream air speed (V1). But this is not what the Betz curve shows. Solving the Betz equation for [Cp = .50] yields [V2/V1 = .617] with 81% of the air in the upstream reference cylinder actually going through the blade circle, and 19% bypassing the blades due to a radial outward push from the inner expanding air flow as it approaches the blades.Editing Wikipedia 'Betz Limit' derivation section (12/28/11)

----------------------------P = Cp x (1/2) x density x S x (v1)^3

Pwind = (1/2) x density x S x (v1)^3

The natural reference for the size of the input cylinder for Pwind (Pin) is to set its area equal to the area of the blades. And while it's not at all clear in the way the betz model normally is presented, it does in fact use a blade area reference cylinder for Pin. I edited Wikipedia to make this point more clear, adding an equation for Pwind (power in the input cylinder).

In the case where the quoted betz efficiency is 59.25% (maximum) the area of the airflow that will actually go through the blades far upstream has only 2/3rd the area of the blades. This air, which slows down to 1/3rd of its initially velocity, does in fact have 88.9% of its energy extracted by the turbine. Efficiency is defined as the ratio (Pout/Pin). So what's going on is that the betz model, by calculating Pin using a cylinder with an area the size of the blades, is including a ring of air that will bypass the blades (flow around the outside) and have zero energy extracted from it. The 3/2 larger energy of Pin reduces the 88.9% efficiency (figured from the velocity change) by 2/3rd to 59.3% the betz limit [0.666 x 88.9% = 59.3%].

In other words the betz model when looked at carefully says at any ratio of speeds some of the air in the blade area reference cylinder will be pushed radially outward (by the expanding, slowing inner air) such that it goes around the blades. If this model is valid (it probably is largely true), it makes the efficiency always lower than the input/output speed ratios would predict, or conversely it makes the input/output speed ratios higher than the turbine efficiency would indicate.

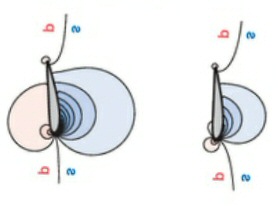

Betz

model applied to modern turbines(Dec 2012)

Previously

I had been assuming that for 50% efficient turbines air passing through

the blades was slowing to 70.7% of the initial velocity, but I now think

the betz model is probably right in showing that some air will go around

the turbine blades, so 70.7% is too high. I solved the Betz equations (above)

for [Cp = .50], and the result is [V2/V1 = .617] with 81% of the air in

the (blade area) reference cylinder passing through the blade circle and

19% bypassing it.

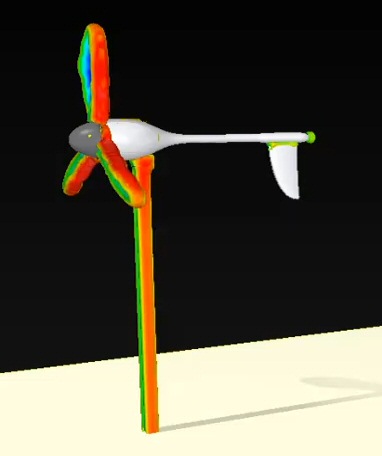

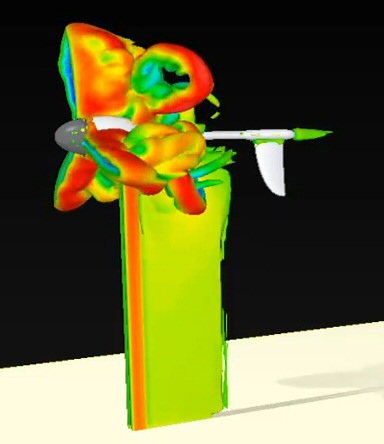

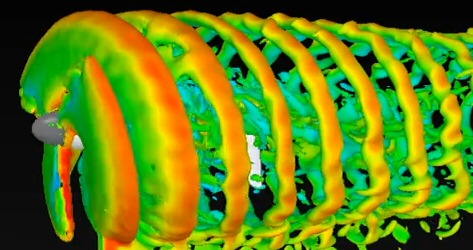

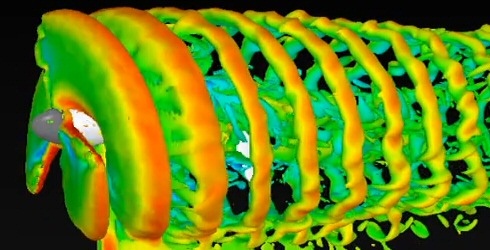

Below is a sketch I made showing the expanding air cylinder for a slowing of the air to 61.7% of initial speed. The betz limit for this speed ratio (see below) is 50%, so this is the Betz upper end for a real modern wind turbine. A 50% efficient wind turbine operating with an exit speed of 61.7% of input speed would be at 100% of its betz limit! I drew the sketch on graph paper to show the size of the inner 81% air column that expands to actually go through the blade circle. Since area goes as radius squared, air that goes through the blade circle is in a cylinder whose radius is about 90% of the blade radius. The outer 10% radius ring of air is pushed outward by the inner expanding air as it loses energy to the blades causing it to bypass the blades.

50% mystery => 62% mystery

Note the air actually

passing through the blades (@ .617) retains only 38% of its initial kinetic

energy. So the 50% efficiency mystery becomes the 62% efficiency mystery!

Upper end estimate of input/output velocity values

for a typical large turbine

with efficiency (power coefficient) of 50%.

Speed change probably mostly occurs within +/- 0.3

radius

What does this mean?

I originally

thought above was merely an upper (Betz) limit for the downstream air speed

at 50% efficiency. But thinking about this, if the Betz model really does

captures the key aspects of air flow (my guess is it does), then what this

is telling us is that this is an estimate of the actual downstream air

speed. (And this is the spin I put on it in my Wikipedia edit.)

Betz calculation for above

Here is the

betz efficiency calculation for the figure above.

Pout/Pwind = (1/2) [ 1 + (v2/v1) - (v2/v1)^2 - (v2/v1)^3]

Betz equation

= (1/2) [ 1 + (.617) - (.617)^2 - (.617)^3]

= (1/2) [ 1 + .617 - .381 - .235]

= 0.50

(50% efficiency, lossless wind turbine)

For the air going through the blades (inner cylinder) the efficiency based on velocity changes is [ 1 - .617^2 = 62%]. This is reduced by the increase in Pin by increasing the input cylinder from .8085 A1 to A1 (area of the blades). 62% x .8085 = 50%. So air slowing to 61.7% of the input speed, would mean real turbines are operating right at the theoretical limit predicted by this model. This is the upper end of the output speed, and it could be lower if real turbines operate below the Betz limit.

The betz model says nothing about over what distance the air velocity changes, but from various hints (tip speed = 7 and computer simulations) I suspect most of the speed change occurs within about 0.3 radius on both sides of the blade, so that's how the figure is drawn. I drew straight lines in the figure, but obviously the real air flow would be a smoothed version.

Stepping back

this makes my input puzzle about how the blade extracted 50% of the input

air worse, because of the air actually passing through the blade circle

(vs flowing around the outside) the energy extraction is 62%!

------------------------------------------

My thoughts on efficiency ---

My first thought

is I am totally amazed that large (three blade, horizontal) turbines

can capture anywhere near half the kinetic energy of the blowing air molecules.

Look at the pictures. The most striking thing visually is that the blades

on a large turbine are tiny (tangentially)! The blades only occupy

maybe 3% of the area swept out! This is totally different from a high speed

cooling fan where blades occupy 50% or more of the area swept out. On first

glance it seem that with such small blades, with huge open space and slow

rotation speeds that most of the air molecules would just pass through

without hitting the blades. It's common sense that the air molecules have

to hit the blades, or approach within a distance roughly comparable

to the size of the airfoil (based on airfoil pressure curves), to transfer

momentum and energy to them. If nearly half the wind kinetic energy is

being extracted by the blades, then it seems to me that nearly all of the

air molecules passing through the swept area must be coming fairly close

to a blade.

Airfoil treatment of blade efficiency

The discussions

I find of blade efficiency are usually in terms of airfoils, discussions

of lift, drag and stall. Clearly there is more than a century of experience,

theory and modelling of propellers for airplanes and boats, about which

I know essentially nothing. Visually the blades of a turbine look a lot

like modern helicopter blades, and they may very well be doing basically

(in hovering) the same job. In a hovering helicopter it's got to be a major

objective is to transfer power (or momentum) to the air efficiently to

minimize the power out of the engine.

When operating at the peak of the power factor curve the air is said to provide 'lift' to the blade, and it is the lift that gives (rotation) force and torque. Enercon blade patent 6,899,523 calls the fall off in power factor on the left side of the peak the 'stall' region, defined as higher wind speed (for a given blade speed) causing the air flow to 'break away' (I presume this means laminar flow is lost) from the blade's suction side. The stall causes lift and hence torque to fall off dramatically. (It also points out that stall caused by wind gusts causes a positive feedback. High winds lower torque, which lowers blade rotation speed, which further lowers the tip speed ratio. A classic workaround to prevent blade stall from gusts is to operate a little above the peak of the curve (blade speed a little too high. Gust stall always begins near the hub where blade velocity is lowest. The improvement of the patent is to shape the blade such that only a small region stalls. This has the effect of broadening the power coefficient curve.

2.5 Mw Clipper (USA)

The unusal

feature of the Clipper is that it uses an usual gearbox with four output

shafts. This allows them to use four 1/4th size generators. They use four

PM generators not induction generators. The nacelle (top structure) in

pictures is also very small. One reason it's small is the PM generators

are quite small and all mounted on the same backplate. They say a standard

gear box is a three stage planetary. Instead they use a two stage helical

distributed design that has four output shafts driving four PM generators.

They say the conventional system used brushes and slip rings to excite

the rotor (this is what double fed means). The go to DC and chop it to

AC using high capacity IGBT's. The Clipper has been installed by First

Wind in a big Utah wind farm.

Clipper is manufactured in Cedar Rapids Iowa (their only factory) with factory capacity of 350 turbines per year. From its annual report Clipper appears to be a new US company (offices in UK too) and the 2.5 Mw turbine is their first product. 2008 revenue: 737 million (sold 248 turbines), 2007 revenue: 24 million. Clippers finances in 2009 were strengthened when a big industrial company (company that owns Pratty and Whitney) boought a 50% stake. According to Wikipedia the taxpayers (via DOE and NREL) funded the development of the 2.5 Mw turbine. Clipper spent 300 million on ("remediation"), translation: fixing bad blades in the field !! They hope in future to install 2000 2.5 Mw Clippers in a 5 Gw project called Titan Wind Project located in South Dakota. This project needs government money to build transmission lines to the field.

Liberty Clipper 2.5 Mw (four PM generators)

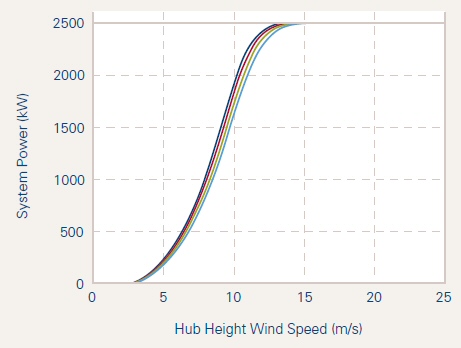

Difference in curves is 13% difference in blade length

(Ref: 10 m/s is 22.4 mph wind)

This curve is interesting. Linearizing the upper part of the S curve it hits saturation at about 12 m/sec. At half this this (6 m/sec) the cubic power relation would predict about 300 kw and that's about what the curve shows. Also there is an inflection point at about 2.2 Mw (10.5 m/s). My guess is that the rotor speed max (15.5 rpm) is at this wind speed and that's why power begins to roll off (maybe with some pitch increase too). The speed spec ratio is 15.5/9.6 = Applying the speced ratio of speeds

Rotor speed

9.6 to 15.5 rpm (6.3 to 3.9 sec rotation time)

Speed ratio

1.61 = [15.5 rpm/9.6 rpm]

Blade length

43.2 m (142 ft)

Tower/hub height

80 m (263 ft)

Gearbox type

two stage helical

Gearbox ratio

73 = [1,133 rpm/15.5 rpm]

Power

2,500 Kw

Voltage

690 VAC

Generator speed

702 to 1,133 rpm

Generator type

synchronous PM (four), 660kw @ 1,133 rpm

DC Link voltage

1,320 VDC @ rated power

817 VDC min (if output rectified)

Power converter

4X, IGBT, six pulse, outputting 690 VAC 50/60 hz

(4x suggests that each PM generator has its own IGBT converter)

(690 VAC would be compatible with 817 VDC bus if it was

peak voltage, and .707 x 690 VAC = 488 VAC)

Tip speed ratio

(@ 10 m/sec)

(3.14 x 2 x 43.2 m radius)/period @ 10 m/sec)/10 m/sec

(271 m/4.45 sec)/10 m/sec

6.1 (est)

The Clipper is quite similar to the Nordex. Clipper speed range is small too at 1.61. The big difference is Clipper uses four small PM generators instead of induction. Also operates at higher voltage, so current in each generator is about much lower, about 500 A = [660 kw/1,329 VDC]. Don't see any survivable wind speed spec on Clipper. German roots? Only factory is in Iowa, but the regulatory qualifications are mostly German.

http://www.clipperwind.com/pdf/liberty_brochure.pdf

Clipper has somehow got its foot in the door to build a really big offshore turbine off UK. In 2008 headline had it at 7.5 Mw, but as of Sept 09 it's now to be a monster 10 Mw turbine. UK government is kicking in millions to build a blade factory in UK for these turbines. Subassembly testing in 2010 and 10 Mw prototype is go up onshore in late 2011. Scale drawings (below) show it dwarfs a 2.5 Mw turbine. From fundamental scaling it needs to be twice as large as a 2.5 Mw turbine to sweep out x4 the area. (It's temping to say 10Mw is approaching the size limit for practical turbines, but people probably thought that about 1.5 Mw units ten years ago!)

http://www.clipperwind.com/pdf/Recharge_18_September_2009_pg_4.pdf

Nordex

2.5 Mw electrical specs (German)

Here is the

usable range power vs speed spec of the 2.5 Mw Nordex wind turbine. This

turbine hits its maximum power about 31 mph, but at 12 mph it is only putting

out 10% of its maximum power.

Rotor speed

10.8 to 18.9 rpm (5.6 to 3.2 sec rotation time)

Speed ratio

1.75 = [18.9 rpm/10.8 rpm]

Blade length

38.8 m (127 ft)

Gearbox type

Planetary

Gearbox ratio

68.7

Power

2,500 Kw

Voltage

660 V

Generator speed

740 to 1,300 rpm

Generator type

asynchronous double-fed (liquid cooled)

Grid connection

via IGBT converter

Tip speed ratio

(@ 10 m/sec)

(3.14 x 2 x 38.8 m radius)/period @ 10 m/sec)/10 m/sec

(243 m/3.8 sec)/10 m/sec

6.4 (est)

Notice the remarkably small working rotation ratio of the blade (& turbine) [18.9 rmp/10.8 rpm = 1.75]. This looks inconsistent with the power range vs speed table. 1.75 cubed is only 5.5, so that would imply a power range for a 2.5 Mw turbine of about 500 kw to 2.5 Mw, but the low end is much lower than 500 kw. Puzzled. In videos of big turbines I count maybe 4.5 sec per rotation, which looks pretty slow, and that fits nicely with the spec range of 3.2 to 5.6 seconds.

The gearbox

steps up the blade speed x68.9 to drive a 2.5 Mw AC generator 740 to 1,300

rpm. Asynchronous means this is an induction generator (induction

motor run backwards). Double fed probably either means its got separate

double windings (or maybe two generators on same shaft). The generator

output AC power is converted to 660 VDC. Very likely AC to DC conversion

is via one or two IGBT controllers that control the induction generator.

|

m/sec |

kw |

ratio (10 m/s baseline) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

limit |

|

Nordex 2/3/2.5 Mw spec sheet

http://www.nordex-online.com/fileadmin/MEDIA/Produktinfos/EN/Nordex_N80_2500_GB.pdf

Northern Power --- 2.2 Mw direct drive turbine (upgraded

to 2.3 Mw)

Northern Power System

has in development a 2.2 Mw turbine for grid farms. What's very interesting

about the Northern 2.2 Mw is that it's to be a scaled up version of their

100 kw unit, and like the 100 kw unit will have no gear box. It will be

'PM direct drive', so its big PM generator will have to operate at the

blade frequency of a big turbine (10 to 20 rpm), which is three or six

times lower than their current 100 kw turbine (59 rpm). And it will be

operating at a frequency x50 to x100 lower than generators (PM or induction)

in other big turbines.

Northern has raised 50 million to do this development, but is that enough? The other much bigger turbine companies build separate factories just for blades or towers and ship them around the world. Northern is a small company. However, I did see that a sewer pipe company in CA has expanded into making towers, so maybe they can buy some of the components they need. Or maybe if they can develop and prove out their big direct drive PM generator, they can be acquired.Northern Power (update 10/26/11)Hail Mary pass --- Other turbine companies have scaled up the multi-Mw turbines in small steps of two or less: 650 kw, 1.5 Mw, 2.5 Mw. Small Northern is scaling up by x22 (100 kw to 2.2 Mw). Sell stock short? (They built a 1.5 Mw test generator in 2005)

Big news is that as of Mar 2011 Northern Power has brought their 2.3 Mw direct drive turbine to market. Web site says the new owners since 2008 have invested 100 million. They better sell well because looking at the pictures you can see it takes a big factory to manufacture all the huge parts in a 2.3 Mw turbine. As of Mar 2011 they have built and installed a single prototype 2.3 Mw in Michigan (built in a factory they have built in Michigan). A couple of months later they have received orders for two.

Northern

Power 2.3 Mw direct drive turbine

Rated power

2.3 Mw

Rotor speed

10 - 15 rpm (4 - 6 sec rotation time)

Speed ratio

1.50 [15 rpm/10 rpm]

Wind speed

3 m/s (cut in), 25 m/s (cut out)

Hub height

80 / 98 m

Rotor dia

93 m (100 m option)

generator

PM direct drive (no gearbox), liquid cooled

converter

IGBT, proprietary circuit, liquid cooled

grid voltage

10 - 34.5 Kv

rotor (assembly, fiberglass blades)

kg

nacelle

kg

tower (steel)

kg

Tip speed ratio

(@ 10 m/sec)

(3.14 x 93 m radius)/period @ 10 m/sec)/10 m/sec

(292 m/4.6 sec)/10 m/sec

6.3 (est)

Curiously small speed ratio of 1.5. I understand why the speed ratio is small in a double fed induction machine, but not why is it is small in a direct drive turbine. The Enercon speed ratio is over 3: 1.

Conversion converts variable power from PM generator to DC then chops DC to grid freq and up through transformer.

2.3 Mw PM generator ring mounted directly behind blade

hub

PM direct drive generator ring (2.3 Mw)

Really cool animated video from Northern Power showing the inside of the nacelle

http://www.northernpower.com/utility-wind-power/northern-power-2.3.php

Scaling up the generator

Power = [torque

x speed] so to load the blades of the Northern big turbine to extract 2.2

Mw the magnetic torque of the generator will have to be scaled way up from

their 100 kw turbine, maybe x88 = [x22 for 2.2 Mw vs 100 kw and x4 for

15 rpm vs 59 rpm blade speed]. If the air gap in a bigger generator is

the same as in the smaller one (maybe not realistic), then the lateral

(sideways) forces of each small region of the air gap stay constant and

the total local lateral force increases as air gap area (radius x length).

Rotational torque depends on how far from the axis the lateral force is

generated [torque = radius x force], so the torque of the generator will

scale as (radius^2 x length).

In other words the torque of a machine is (approx) proportional to its volume and weight. Low speed for a given power means high torque and high torque means a big generator! First order scaling says the penalty for removing a 100:1 gearbox (for same power) is an increase in weight of the generator by x100! In practice there may be tricks that can be played like making the generator more in the form of a ring with a hollowed out interior (like a bicycle wheel). To scale up a 100 kw generator to 2.2 Mw and account for the lower blade speed, the torque must go up by x88 = [ x22 higher power and x4 lower speed], so the generator needs to expand in each dimension by about a factor of 4.45 = [cube root{88}] and could weigh x88 the weight of the 100 kw PM generator.

Here is a calculation of the torque for the 2.2 Mw unit (I'll use same blade speed for full power as the 100 kw turbine: 13 rpm).

torque = power/w

= 2.2 x 10^6/(13 rpm x (1 min/60 sec) x 2 pi)

= 2.2 x 10^6/(1.36 rad/sec)

= 1.6 x 10^6 n-m x (1ft-lb/1.35 n-m)

= 1.19 x 10^6 ft-lb

One million two hundred thousand ft-lb is a shit-load of torque. I looked up the torque available from a company I used to work with who makes very large PM motors (to 400 hp) for industry (Powertec) and their idea of high torque is 3,000 ft lbs, less than 1% of what this turbine needs. In the ABB large family of turbines for wind they indicate they make (or can make) direct drive PM turbines designed for the low rpm of a large turbine. I can't find any detailed specs, but apparently this ABB direct drive PM generator is good to 1.5 Mw. Does anybody actually use large PM direct drive turbines? Outside of Northern, who has a 2.2 Mw PM gearless in development, I can't find anybody.

Doing some Googling I found large direct drive wind turbines are not new. In an ABB survey paper (2001) of the ten largest wind turbine manuf one of them (Enercon) was already gearless (10 to 24 rpm) at a power level of 1.8 Mw. So what is it that Northern is doing that is new? Maybe its the use of PM in a big ring turbine, or are they just going to buy it from ABB?

Bingo